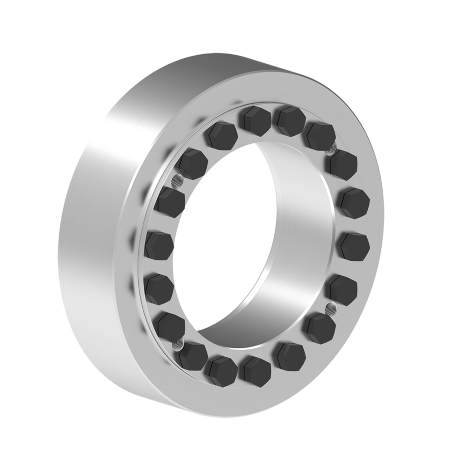

Shrink Discs RfN 4181

Two part shrink heavy duty series – with additional guide mechanism for the inner ring. For the transmission of maximum torques.

Technical Data & CAD Models

| CAD |

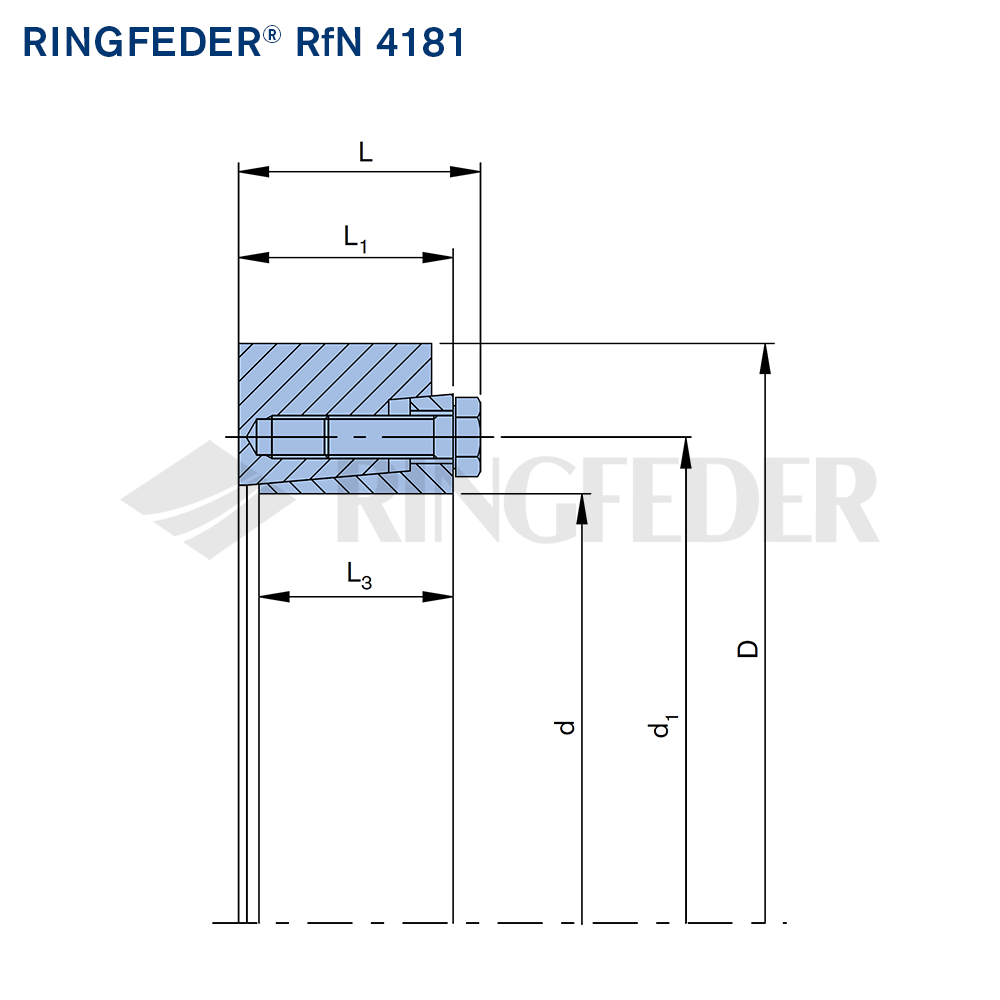

d

mm |

D

mm |

dw

mm |

L

mm |

L1

mm |

L3

mm |

T

Nm |

Fax

kN |

DG

mm |

TA

Nm |

Gw

kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 220 | 370 | 160 | 115,8 | 103,3 | 87 | 160000 | 2000 | 20 | 570 | 52,11 | |

| 220 | 370 | 170 | 115,8 | 103,3 | 87 | 182000 | 2150 | 20 | 570 | 52,11 | |

| 220 | 370 | 180 | 115,8 | 103,3 | 87 | 206000 | 2300 | 20 | 570 | 52,11 | |

| 240 | 405 | 170 | 121,4 | 108,9 | 92 | 190000 | 2250 | 20 | 570 | 66,58 | |

| 240 | 405 | 180 | 121,4 | 108,9 | 92 | 215000 | 2400 | 20 | 570 | 66,58 | |

| 240 | 405 | 200 | 121,4 | 108,9 | 92 | 269000 | 2700 | 20 | 570 | 66,58 | |

| 260 | 430 | 190 | 128,4 | 115,9 | 102 | 247000 | 2600 | 20 | 580 | 77,29 | |

| 260 | 430 | 200 | 128,4 | 115,9 | 102 | 277000 | 2750 | 20 | 580 | 77,29 | |

| 260 | 430 | 220 | 128,4 | 115,9 | 102 | 340000 | 3100 | 20 | 580 | 77,29 | |

| 280 | 460 | 210 | 146,4 | 133,9 | 121 | 282000 | 2686 | 20 | 570 | 103,28 | |

| 280 | 460 | 220 | 146,4 | 133,9 | 121 | 313000 | 2845 | 20 | 570 | 103,28 | |

| 280 | 460 | 240 | 146,4 | 133,9 | 121 | 380000 | 3167 | 20 | 570 | 103,28 | |

| 300 | 485 | 220 | 154,1 | 139,1 | 122 | 385000 | 3500 | 24 | 980 | 117,05 | |

| 300 | 485 | 230 | 154,1 | 139,1 | 122 | 425000 | 3700 | 24 | 980 | 117,05 | |

| 300 | 485 | 250 | 154,1 | 139,1 | 122 | 505000 | 4050 | 24 | 980 | 117,05 | |

| 320 | 520 | 240 | 156,6 | 141,6 | 124 | 444000 | 3700 | 24 | 980 | 132,1 | |

| 320 | 520 | 250 | 156,6 | 141,6 | 124 | 488000 | 3904 | 24 | 980 | 132,1 | |

| 320 | 520 | 270 | 156,6 | 141,6 | 124 | 580000 | 4296 | 24 | 980 | 132,1 | |

| 340 | 570 | 250 | 167,5 | 152,5 | 135 | 564000 | 4500 | 24 | 980 | 184,25 | |

| 340 | 570 | 260 | 167,5 | 152,5 | 135 | 612000 | 4700 | 24 | 980 | 184,25 | |

| 340 | 570 | 270 | 167,5 | 152,5 | 135 | 668000 | 4950 | 24 | 980 | 184,25 | |

| 360 | 590 | 270 | 182,7 | 167,7 | 150 | 658000 | 4850 | 24 | 980 | 208,11 | |

| 360 | 590 | 280 | 182,7 | 167,7 | 150 | 712000 | 5100 | 24 | 980 | 208,11 | |

| 360 | 590 | 300 | 182,7 | 167,7 | 150 | 825000 | 5500 | 24 | 980 | 208,11 | |

| 380 | 640 | 290 | 185,1 | 168,1 | 148 | 735000 | 5069 | 27 | 1450 | 247,5 | |

| 380 | 640 | 300 | 185,1 | 168,1 | 148 | 790000 | 5266 | 27 | 1450 | 247,5 | |

| 380 | 640 | 310 | 185,1 | 168,1 | 148 | 845000 | 5452 | 27 | 1450 | 247,5 | |

| 390 | 650 | 290 | 186,3 | 167,6 | 144 | 903000 | 6250 | 30 | 1900 | 259,55 | |

| 390 | 650 | 300 | 186,3 | 167,6 | 144 | 970000 | 6450 | 30 | 1900 | 259,55 | |

| 390 | 650 | 320 | 186,3 | 167,6 | 144 | 1101000 | 6950 | 30 | 1900 | 259,55 | |

| 420 | 670 | 320 | 203,9 | 186,9 | 166 | 969000 | 6056 | 27 | 1450 | 284,75 | |

| 420 | 670 | 330 | 203,9 | 186,9 | 166 | 1038000 | 6291 | 27 | 1450 | 284,75 | |

| 420 | 670 | 350 | 203,9 | 186,9 | 166 | 1183000 | 6762 | 27 | 1450 | 284,75 | |

| 440 | 740 | 340 | 212,9 | 195,9 | 178 | 1212000 | 7129 | 27 | 1450 | 398 | |

| 440 | 740 | 350 | 212,9 | 195,9 | 178 | 1292000 | 7383 | 27 | 1450 | 398 | |

| 440 | 740 | 370 | 212,9 | 195,9 | 178 | 1460000 | 7892 | 27 | 1450 | 398 | |

| 480 | 790 | 380 | 243,7 | 225,0 | 201 | 1815000 | 9552 | 30 | 1900 | 495,4 | |

| 480 | 790 | 390 | 243,7 | 225,0 | 201 | 1920000 | 9845 | 30 | 1900 | 495,4 | |

| 480 | 790 | 410 | 243,7 | 225,0 | 201 | 2118000 | 10331 | 30 | 1900 | 495,4 | |

| 500 | 835 | 400 | 238,7 | 220,0 | 198 | 2054000 | 10270 | 30 | 1900 | 626,3 | |

| 500 | 835 | 410 | 238,7 | 220,0 | 198 | 2145000 | 10463 | 30 | 1900 | 626,3 | |

| 500 | 835 | 430 | 238,7 | 220,0 | 198 | 2377000 | 11055 | 30 | 1900 | 626,3 | |

| 530 | 850 | 430 | 260,0 | 240,0 | 206 | 2397000 | 11150 | 30 | 1900 | 653,4 | |

| 530 | 850 | 440 | 260,0 | 240,0 | 206 | 2520520 | 11457 | 30 | 1900 | 653,4 | |

| 530 | 850 | 460 | 260,0 | 240,0 | 206 | 2777417 | 12076 | 30 | 1900 | 653,4 | |

| 560 | 940 | 450 | 260,0 | 240,0 | 206 | 2545000 | 11311 | 30 | 1900 | 748,7 | |

| 560 | 940 | 460 | 260,0 | 240,0 | 206 | 2670006 | 11609 | 30 | 1900 | 748,7 | |

| 560 | 940 | 480 | 260,0 | 240,0 | 206 | 2929521 | 12206 | 30 | 1900 | 748,7 | |

| 590 | 960 | 470 | 380,0 | 361,0 | 286 | 4012000 | 17072 | 30 | 1900 | 1173,9 | |

| 590 | 960 | 480 | 380,0 | 361,0 | 286 | 4199188 | 17497 | 30 | 1900 | 1173,9 | |

| 590 | 960 | 500 | 380,0 | 361,0 | 286 | 4587043 | 18348 | 30 | 1900 | 1173,9 | |

| 620 | 970 | 500 | 304,0 | 285,0 | 244 | 3402000 | 13608 | 30 | 1900 | 886,7 | |

| 620 | 970 | 520 | 304,0 | 285,0 | 244 | 3708000 | 14261 | 30 | 1900 | 886,7 | |

| 620 | 970 | 540 | 304,0 | 285,0 | 244 | 4028000 | 14918 | 30 | 1900 | 886,7 | |

| 660 | 1040 | 530 | 418,0 | 396,0 | 310 | 5758000 | 21750 | 36 | 3500 | 1448,2 | |

| 660 | 1040 | 550 | 418,0 | 396,0 | 310 | 6236900 | 22680 | 36 | 3500 | 1448,2 | |

| 660 | 1040 | 570 | 418,0 | 396,0 | 310 | 6735919 | 23635 | 36 | 3500 | 1448,2 | |

| 700 | 1140 | 560 | 315,0 | 294,0 | 260 | 4518700 | 16138 | 33 | 2700 | 1467,5 | |

| 700 | 1140 | 580 | 315,0 | 294,0 | 260 | 4880000 | 16828 | 33 | 2700 | 1467,5 | |

| 700 | 1140 | 600 | 315,0 | 294,0 | 260 | 5258000 | 17527 | 33 | 2700 | 1467,5 | |

| 750 | 1150 | 600 | 340,0 | 428,0 | 360 | 7669000 | 25563 | 36 | 3500 | 1847,5 | |

| 750 | 1150 | 620 | 450,0 | 428,0 | 360 | 8228643 | 26544 | 36 | 3500 | 1847,5 | |

| 750 | 1150 | 650 | 450,0 | 428,0 | 360 | 9106895 | 28021 | 36 | 3500 | 1847,5 | |

| 800 | 1230 | 640 | 373,0 | 352,0 | 296 | 6897960 | 21226 | 33 | 2700 | 1894,4 | |

| 800 | 1230 | 660 | 373,0 | 352,0 | 296 | 7378000 | 22358 | 33 | 2700 | 1894,4 | |

| 800 | 1230 | 700 | 373,0 | 352,0 | 296 | 8390500 | 23973 | 33 | 2700 | 1894,4 |

| CAD |

d inch |

D inch |

dw inch |

L inch |

L1 inch |

L3 inch |

T ft-lbs |

Fax lbs |

DG mm |

TA ft-lbs |

Gw lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 8.661 | 14.567 | 6.299 | 4.559 | 4.067 | 3.425 | 118010 | 449952 | M20 | 420 | 115 | |

| 8.661 | 14.567 | 6.693 | 4.559 | 4.067 | 3.425 | 134236 | 483698 | M20 | 420 | 115 | |

| 8.661 | 14.567 | 7.087 | 4.559 | 4.067 | 3.425 | 151938 | 517445 | M20 | 420 | 115 | |

| 9.449 | 15.945 | 6.693 | 4.780 | 4.287 | 3.622 | 140137 | 506196 | M20 | 420 | 147 | |

| 9.449 | 15.945 | 7.087 | 4.780 | 4.287 | 3.622 | 158576 | 539942 | M20 | 420 | 147 | |

| 9.449 | 15.945 | 7.874 | 4.780 | 4.287 | 3.622 | 198404 | 607435 | M20 | 420 | 147 | |

| 10.236 | 16.929 | 7.480 | 5.055 | 4.563 | 4.016 | 182178 | 584938 | M20 | 428 | 170 | |

| 10.236 | 16.929 | 7.874 | 5.055 | 4.563 | 4.016 | 204305 | 618684 | M20 | 428 | 170 | |

| 10.236 | 16.929 | 8.661 | 5.055 | 4.563 | 4.016 | 250771 | 697426 | M20 | 428 | 170 | |

| 11.024 | 18.110 | 8.268 | 5.764 | 5.272 | 4.764 | 207992 | 604286 | M20 | 420 | 228 | |

| 11.024 | 18.110 | 8.661 | 5.764 | 5.272 | 4.764 | 230857 | 640057 | M20 | 420 | 228 | |

| 11.024 | 18.110 | 9.449 | 5.764 | 5.272 | 4.764 | 280274 | 712499 | M20 | 420 | 228 | |

| 11.811 | 19.094 | 8.661 | 6.067 | 5.476 | 4.803 | 283961 | 787416 | M24 | 725 | 258 | |

| 11.811 | 19.094 | 9.055 | 6.067 | 5.476 | 4.803 | 313464 | 832411 | M24 | 725 | 258 | |

| 11.811 | 19.094 | 9.843 | 6.067 | 5.476 | 4.803 | 372469 | 911153 | M24 | 725 | 258 | |

| 12.598 | 20.472 | 9.449 | 6.165 | 5.575 | 4.882 | 327478 | 832411 | M24 | 725 | 291 | |

| 12.598 | 20.472 | 9.843 | 6.165 | 5.575 | 4.882 | 359930 | 878306 | M24 | 725 | 291 | |

| 12.598 | 20.472 | 10.630 | 6.165 | 5.575 | 4.882 | 427786 | 966497 | M24 | 725 | 291 | |

| 13.386 | 22.441 | 9.843 | 6.594 | 6.004 | 5.315 | 415985 | 1012392 | M24 | 725 | 406 | |

| 13.386 | 22.441 | 10.236 | 6.594 | 6.004 | 5.315 | 451388 | 1057387 | M24 | 725 | 406 | |

| 13.386 | 22.441 | 10.630 | 6.594 | 6.004 | 5.315 | 492697 | 1112448 | M24 | 725 | 406 | |

| 14.173 | 23.228 | 10.630 | 7.193 | 6.602 | 5.906 | 485316 | 1091134 | M24 | 725 | 459 | |

| 14.173 | 23.228 | 11.024 | 7.193 | 6.602 | 5.906 | 525144 | 1147378 | M24 | 725 | 459 | |

| 14.173 | 23.228 | 11.811 | 7.193 | 6.602 | 5.906 | 608489 | 1237368 | M24 | 725 | 459 | |

| 14.961 | 25.197 | 11.417 | 7.287 | 6.618 | 5.827 | 542108 | 1140403 | M27 | 1070 | 546 | |

| 14.961 | 25.197 | 11.811 | 7.287 | 6.618 | 5.827 | 582674 | 1184724 | M27 | 1070 | 546 | |

| 14.961 | 25.197 | 12.205 | 7.287 | 6.618 | 5.827 | 623240 | 1226569 | M27 | 1070 | 546 | |

| 15.354 | 25.591 | 11.417 | 7.335 | 6.598 | 5.669 | 666018 | 1406100 | M30 | 1400 | 572 | |

| 15.354 | 25.591 | 11.811 | 7.335 | 6.598 | 5.669 | 715435 | 1451095 | M30 | 1400 | 572 | |

| 15.354 | 25.591 | 12.598 | 7.335 | 6.598 | 5.669 | 812065 | 1563583 | M30 | 1400 | 572 | |

| 16.535 | 26.378 | 12.598 | 8.026 | 7.356 | 6.535 | 714698 | 1362455 | 27 | 1069 | 628 | |

| 16.535 | 26.378 | 12.992 | 8.026 | 7.356 | 6.535 | 765589 | 1415324 | 27 | 1069 | 628 | |

| 16.535 | 26.378 | 13.780 | 8.026 | 7.356 | 6.535 | 872536 | 1521288 | 27 | 1069 | 628 | |

| 17.323 | 29.134 | 13.386 | 8.382 | 7.713 | 7.008 | 893925 | 1603854 | 27 | 1069 | 877 | |

| 17.323 | 29.134 | 13.780 | 8.382 | 7.713 | 7.008 | 952930 | 1660998 | 27 | 1069 | 877 | |

| 17.323 | 29.134 | 14.567 | 8.382 | 7.713 | 7.008 | 1076841 | 1775511 | 27 | 1069 | 877 | |

| 18.898 | 31.102 | 14.961 | 9.594 | 8.858 | 7.913 | 1338690 | 2146688 | M30 | 1400 | 1092 | |

| 18.898 | 31.102 | 15.354 | 9.594 | 8.858 | 7.913 | 1416134 | 2212536 | M30 | 1400 | 1092 | |

| 18.898 | 31.102 | 16.142 | 9.594 | 8.858 | 7.913 | 1562173 | 2321758 | M30 | 1400 | 1092 | |

| 19.685 | 32.874 | 15.748 | 9.398 | 8.661 | 7.795 | 1514969 | 2308049 | M30 | 1400 | 1381 | |

| 19.685 | 32.874 | 16.142 | 9.398 | 8.661 | 7.795 | 1582088 | 2351423 | M30 | 1400 | 1381 | |

| 19.685 | 32.874 | 16.929 | 9.398 | 8.661 | 7.795 | 1753204 | 2484468 | M30 | 1400 | 1381 | |

| 20.866 | 33.465 | 16.929 | 10.236 | 9.449 | 8.110 | 1767936 | 2508482 | M30 | 1400 | 1440 | |

| 20.866 | 33.465 | 17.323 | 10.236 | 9.449 | 8.110 | 1859040 | 2577550 | M30 | 1400 | 1440 | |

| 20.866 | 33.465 | 18.110 | 10.236 | 9.449 | 8.110 | 2048517 | 2716810 | M30 | 1400 | 1440 | |

| 22.047 | 37.008 | 17.717 | 10.236 | 9.449 | 8.110 | 1877095 | 2544704 | M30 | 1400 | 1651 | |

| 22.047 | 37.008 | 18.110 | 10.236 | 9.449 | 8.110 | 1969295 | 2611746 | M30 | 1400 | 1651 | |

| 22.047 | 37.008 | 18.898 | 10.236 | 9.449 | 8.110 | 2160703 | 2746057 | M30 | 1400 | 1651 | |

| 23.228 | 37.795 | 18.504 | 14.961 | 14.213 | 11.260 | 2959099 | 3840790 | M30 | 1400 | 2588 | |

| 23.228 | 37.795 | 18.898 | 14.961 | 14.213 | 11.260 | 3097161 | 3936405 | M30 | 1400 | 2588 | |

| 23.228 | 37.795 | 19.685 | 14.961 | 14.213 | 11.260 | 3383229 | 4127860 | M30 | 1400 | 2588 | |

| 24.409 | 38.189 | 19.685 | 11.969 | 11.220 | 9.606 | 2509186 | 3061473 | M30 | 1400 | 1955 | |

| 24.409 | 38.189 | 20.472 | 11.969 | 11.220 | 9.606 | 2734880 | 3208383 | M30 | 1400 | 1955 | |

| 24.409 | 38.189 | 21.260 | 11.969 | 11.220 | 9.606 | 2970900 | 3356192 | M30 | 1400 | 1955 | |

| 25.984 | 40.945 | 20.866 | 16.457 | 15.591 | 12.205 | 4246882 | 4893228 | M36 | 2580 | 3193 | |

| 25.984 | 40.945 | 21.654 | 16.457 | 15.591 | 12.205 | 4600100 | 5102456 | M36 | 2580 | 3193 | |

| 25.984 | 40.945 | 22.441 | 16.457 | 15.591 | 12.205 | 4968158 | 5317308 | M36 | 2580 | 3193 | |

| 27.559 | 44.882 | 22.047 | 12.402 | 11.575 | 10.236 | 3332821 | 3630663 | M33 | 1990 | 3235 | |

| 27.559 | 44.882 | 22.835 | 12.402 | 11.575 | 10.236 | 3599303 | 3785896 | M33 | 1990 | 3235 | |

| 27.559 | 44.882 | 23.622 | 12.402 | 11.575 | 10.236 | 3878101 | 3943154 | M33 | 1990 | 3235 | |

| 29.528 | 45.276 | 23.622 | 13.386 | 16.850 | 14.173 | 5656363 | 5751061 | M36 | 2580 | 4073 | |

| 29.528 | 45.276 | 24.409 | 17.717 | 16.850 | 14.173 | 6069134 | 5971763 | M36 | 2580 | 4073 | |

| 29.528 | 45.276 | 25.591 | 17.717 | 16.850 | 14.173 | 6716900 | 6304052 | M36 | 2580 | 4073 | |

| 31.496 | 48.425 | 25.197 | 14.685 | 13.858 | 11.654 | 5087673 | 4775341 | M33 | 1990 | 4176 | |

| 31.496 | 48.425 | 25.984 | 14.685 | 13.858 | 11.654 | 5441732 | 5030013 | M33 | 1990 | 4176 | |

| 31.496 | 48.425 | 27.559 | 14.685 | 13.858 | 11.654 | 6188514 | 5393350 | M33 | 1990 | 4176 |

Images & Drawings

Product Characteristics

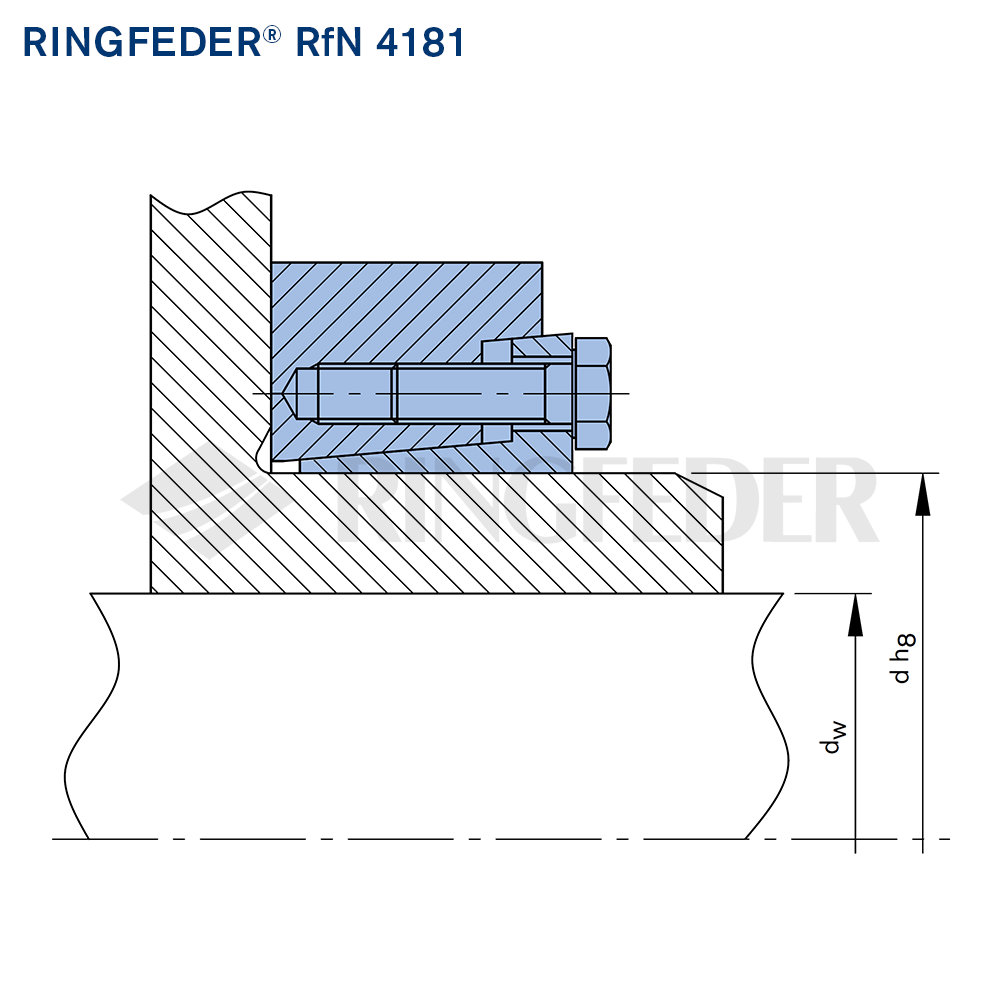

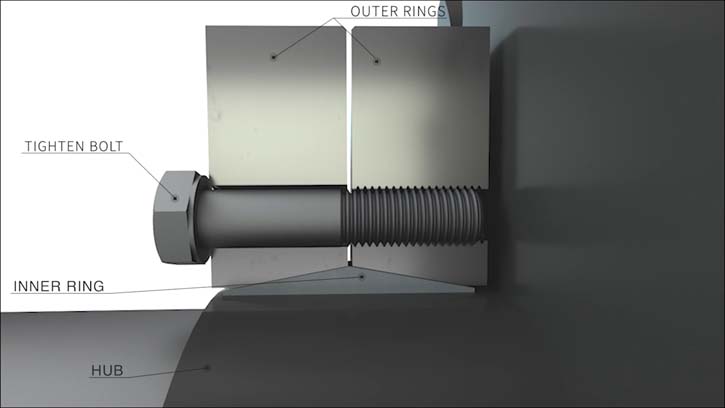

Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances and fine surface finishes, they also need considerable effort with mounting and removal. The shrink disc connection has none of these disadvantages and is better than any of the other usual connection methods with regard to fatigue strength under alternating torsional stress.

- Two part shrink heavy duty series – with additional guide mechanism for the inner ring. For the transmission of maximum torques.

- Unlimited range of applications – RINGFEDER® Shrink Disc connections are suitable for securing all types of hubs onto shafts and axles. Replacing traditional shrink fits, keys and polygon connections, splined shafts etc. So cog wheels and sprockets, levers, lifters, cam discs, pulleys or brake discs, balance wheels, couplings, slip on gear mechanisms, flanges, pulley wheels and rotors can be attached absolutely reliable.

- Highest reliability – applicable for static, dynamic and impact loads.

- Simplified manufacture – only plain shaft and bore diameters with easily achieved surface finish and tolerances are required.

- Fully replaceable – The RINGFEDER® shrink discs work without any positive locking.

- Visual check of the tightening status – minimisation of faults

during assembly. - Easy mounting – RINGFEDER® Shrink Discs use standard

screws and tightened using standard tools. No additional machining or fitting work is required. - Short assembly times - cost savings particularly in series production.

- Low susceptibility to contamination – when the locking screws

are tightened the contact (functional) surfaces are pressed firmly together and prevent the ingress of dirt and moisture. - Easy adjustability – no stops, steps, key-ways, splines etc. are

required therefore, hubs can be located and locked at any point or

angle on the shaft.

Surface finishes

For shaft diameter dw: Peak-to-valley height Ra ≤ 3,2 μm.

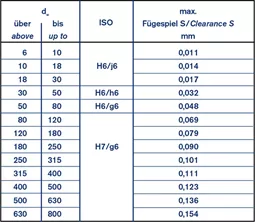

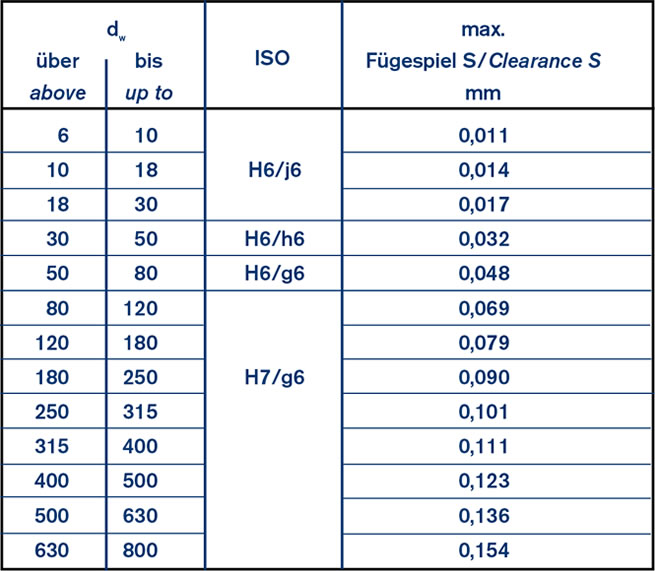

Tolerances

For shaft see table above.

Suitable Industry Solutions

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.