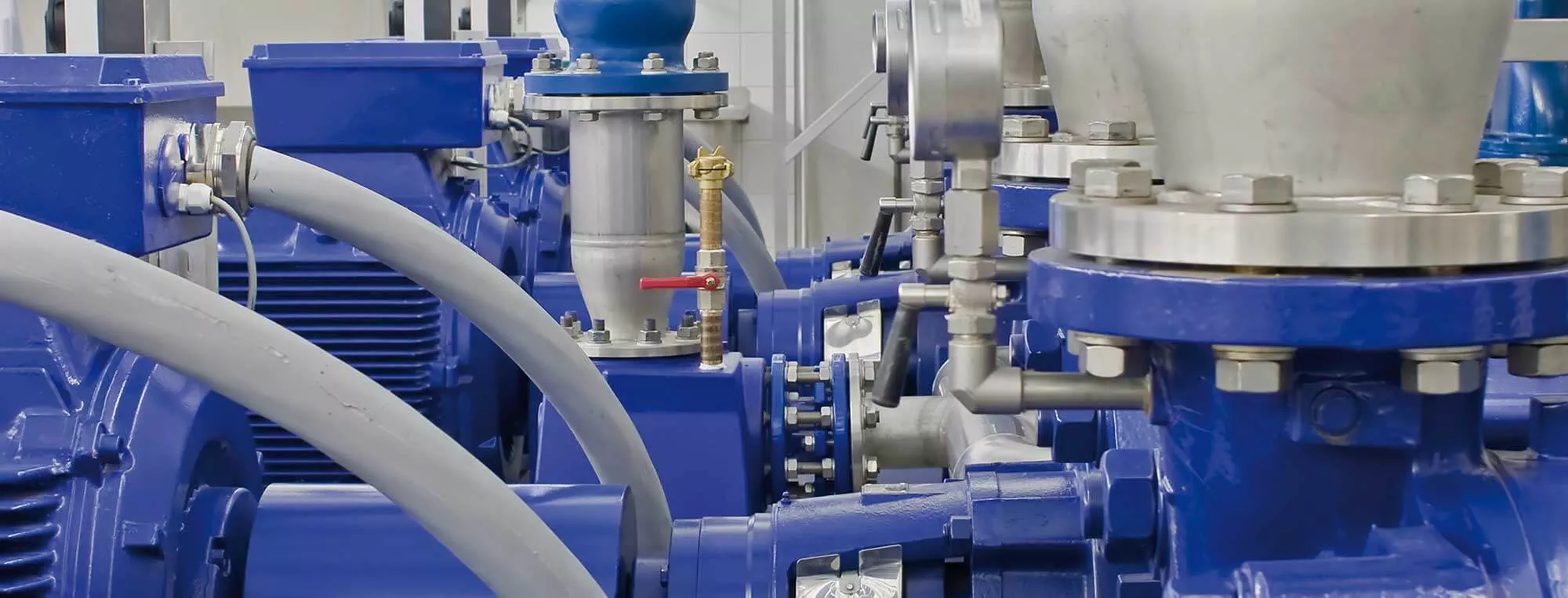

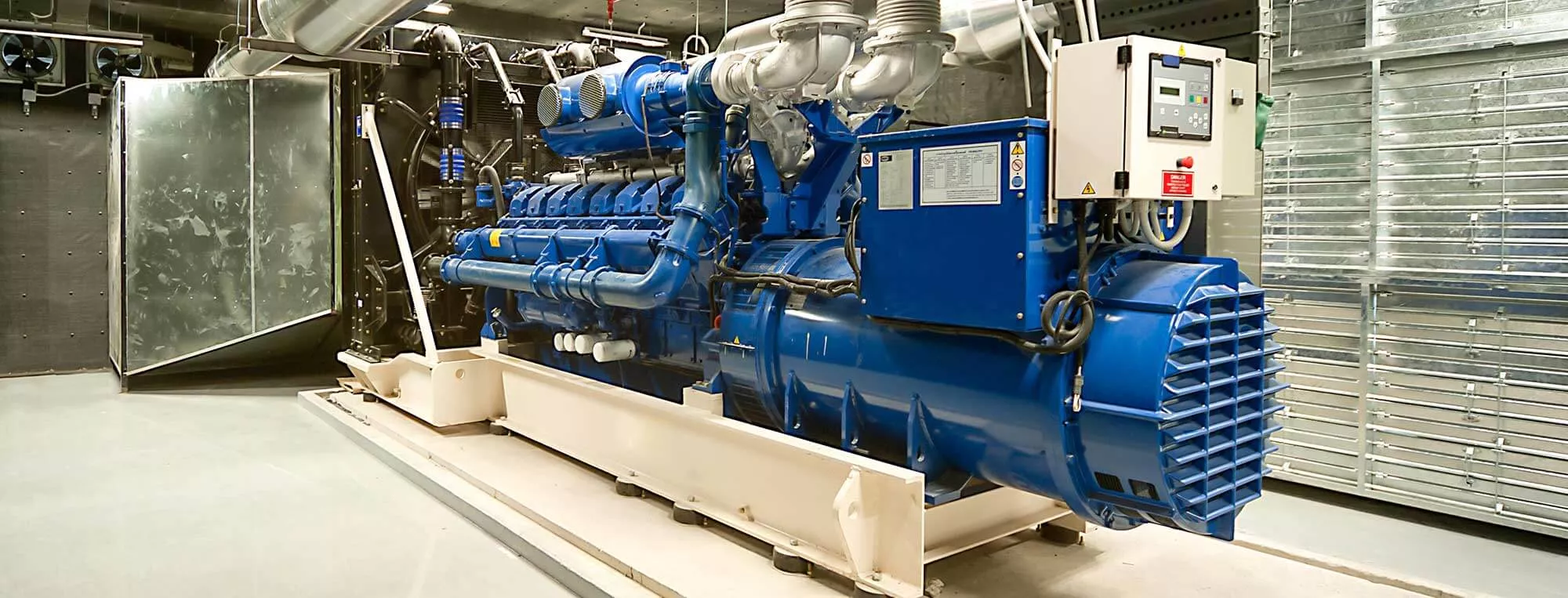

Backlash-Free and Damping Connections for Pump Technology

From miniature pumps for laboratory applications to large-scale facilities of the chemical industry: If shaft connections between the drive and output or shaft-hub connections are to be established in the field of pump technology, users all around the world rely on high-performance coupling and locking devices designed by RINGFEDER®. The key requirements in this field of application are for instance the capability in the drive train to compensate for misalignments, the uncomplicated installation and removal without having to dismount adjoining drive elements as well as distinct torsional flexibility and vibration damping properties. Therefore, in particular damping, fail-safe couplings and frictional, backlash-free locking elements are used, which are dimensioned individually for the respective customer application.

Reliable Gearwheel Mounting in Vacuum Pumps

The complex application of a powerful vacuum pump required the use of a high-precision and backlash-free shrink disc. The challenging transmission torque and the minimum installation dimensions were specified by the customer. Furthermore, the pump gear was to be directly connected to the shrink disc by flange mounting. Specially for this purpose, RINGFEDER® has designed a special shrink disc that meets the requirements posed also with regard to the continuous series application, and which establishes a stable frictional connection to the drive shaft.

Trouble-Free Dismounting for Maintenance Operations

In order to provide for quick and uncomplicated dismounting, RINGFEDER® shrink discs are either self-releasing or are provided with integrated threaded extraction holes. In the specific case of a renowned pump manufacturer, the connection was specially designed for dry installation: Even if the taper surfaces are degreased, the integrated threaded extraction holes provide for quick dismantling and removal. Corresponding provision of these special components at all RINGFEDER® sites guarantees worldwide short-term supply of required spare and replacement components to the customers.

Pump Specific Solutions from the Modular System

Pump rotors of any size and shape must be aligned towards each other with exact precision. For this purpose, the extensive RINGFEDER® standard range offers high-performance locking device solutions in two-piece and three-piece variants. Furthermore, the users are provided with a choice of complete, separated, and half shrink discs depending on the demand and requirement. For the use in small to medium-sized pumps, premium-quality RINGFEDER® locking elements are perfectly suited. For more critical applications, e.g. in large-scale facilities of the chemical sector and the oil industry, special variants with a suitable surface protection or special materials are designed. Compliance of all RINGFEDER® solutions with industry-specific regulations and standards goes without saying. Complemented by the versatile portfolio of consistent and durable shaft couplings, RINGFEDER® is the outstanding system partner for users from the pump sector.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.