Uncompromising Performance under Extreme Conditions

Applications in the sector of mining, surface and underground, are accompanied by extremely rough conditions. Whether you’re dealing with transport materials of a different hardness, size and weight, strong heat and coldness, extreme air humidity, aggressive chemicals or a massive formation of dust and dirt – the systems used such as bucket wheel excavators, impact crushers, clearing and tunnel-digging machines and material conveying systems as well as their components must meet tremendous requirements with regard to their performance and stability. That’s why leading manufacturers all around the world rely on premium-quality, robust coupling systems, damping elements and locking devices designed by RINGFEDER®, which ensure reliable, safe and sustainable operation. RINGFEDER® comprehensively assists its users from this sector in achieving their top goal of maximum operational safety.

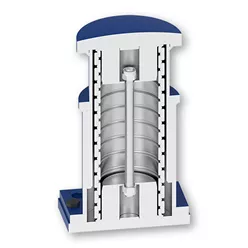

Highly Specific Special Locking Assemblies for Impact Crushers

The locking devices that are applied to connect the rotor shaft and the crushing roll of impact crushers used for the grinding of crushed rock material are for instance exposed to extreme strain in the form of bending torques and radial run-out. In order to avoid negative consequences of these strains on the operational performance and durability of impact crushers, RINGFEDER® has developed a special solution for one of the globally leading manufacturers: The specially designed locking assembly variants, which are based on the RfN 7012 and RfN 7015 series and which are manufactured with high precision are provided with a higher yield strength, a flatter angle of taper and considerably wider pressure rings, thus ensuring the reliable, lower-maintenance function of impact crushers.

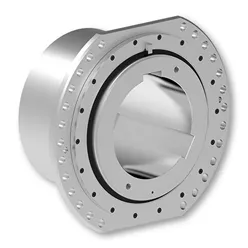

Maximum Operational Safety with an Additional Axial and Radial Load

In order to transport large volumes of bulk material of iron ore or copper ore, coal and other natural resources from mines or opencast mines to corresponding loading points, powerful, large-scale conveyor belts are used. They are driven by pulleys the diameter of which is between 150 and 800 millimetres and which are provided with a drive power of 500 to 6,000 kilowatts – depending on the delivery volume and speed. Premium-quality RINGFEDER® standard and special locking assemblies have stood the test in practice as ideal shaft-hub connection between the drive shaft and the drum base. The consistent and reliable transmission of the required torque is even ensured under extreme additional strain caused by bending torques and radial forces, and also the possibility of quick and easy mounting and removal as well as the direct availability of required replacement products in the case of service operations are guaranteed by this product.

Reliable Performance Underground

Excellent damping and misalignment compensation characteristics, huge torque transmission densities, exceptional robustness even under rough ambient conditions – the torsionally flexible, fail-safe jaw couplings of the RINGFEDER® TNB series have stood the test in demanding mining applications many hundred times over. This also applies to the concrete case of several powerful drives of conveyor belts, used to quickly remove the raw material extracted from an underground mine, where strong heat and the formation of dust as well as very confined spatial conditions are predominant. The premium-quality TNB couplings act as ideal shaft connectors of maximum reliability, stability and service-friendliness in this application.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.