Optimum Performance at the Highest Heights

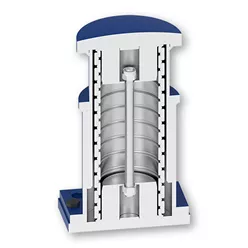

The requirements with regard to elements that are used in the field of aerospace technology are tremendous, multifaceted and complex. If, for example, the mass of 90 tons of a typical medium range aircraft is accelerated to 300 kilometres per hour within a few seconds, mechanically loaded components are particularly exposed to extreme conditions to which they must withstand. After the start until reaching the cruising altitude, also temperature differences of up to 80° Celsius occur within the shortest time, predominately acting on critical areas such as the fuselage, wings and drive. Accordingly, one of our top priorities is to always ensure the trouble-free and safe function of the components used – even in exceptional cases. RINGFEDER® friction springs meet these requirements and, in the sector of aerospace technology, are indispensable safety element for the exact and quick damping of kinetic energy – as standard items or as customer-specific special design.

Industry Solutions for Aviation & Aerospace

Perfectly Damped on the Red Planet

An extremely robust drilling tool on one of the robot arms of the Curiosity Mars Rover made it possible to obtain rock samples from Mars for the first time – in particular also due to the high technology used provided by RINGFEDER®. In order to prevent the complex and susceptible electronics system of the Rover from being damaged, a specially developed friction spring absorbs the shock forces generated during the drilling process and prevents any resonance effects. Due to the vacuum prevailing on Mars as well as the extreme temperature between -140 and +30° Celsius, the RINGFEDER® damping element was designed in high-strength stainless steel and was furthermore provided with a special dry film lubrication. With a diameter of only 18 millimetres, the friction spring effectively absorbs shocks with an energy of up to 6 Joule and therefore plays a decisive role in ensuring the faultless operation of the drilling tool.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.