Diverse Applications, Most Complex Requirements

Backlash-free, metal bellows and elastomer couplings that compensate for misalignments, providing for optimum torque transmission in the packaging and labelling production sector, high-precision, maintenance- and installation-friendly locking assemblies for powerful ball mills used in the field of cement production, friction springs specially designed as effective pre-dampers for roller conveyors in rolling mills used in the steel industry – the range of applications of the premium-quality RINGFEDER® solutions customised for the application in each case is as versatile as that of technology itself. Whether we are speaking of processes such as separating, shredding, moulding, drying, mixing, conveying, refining, or further procedures used for the physical, biological and chemical modification of diverse materials: on the basis of its outstanding expertise and long-standing experience, RINGFEDER® offers tailor-made shaft-hub connections and shaft-shaft connections as well as damping elements in standard and special design, meeting the highest and most complex standards of process engineering – durable, reliable, economical, functional.

Industry Solutions for Process Technology

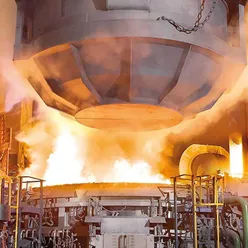

Maximum Performance at Maximum Load: Friction Springs for Melting Furnaces

RINGFEDER® has designed a special damping solution for the application in the arc furnace of steel works, which involves specific requirements as to temperature and load resistance. The melting furnace serves to melt very large and heavy parts of steel scrap (e.g. engine blocks), which fall into the melt from a height of up to ten metres. By the use of a variety of industrial buffers based on RINGFEDER® Friction Springs, which are provided with an absorption capacity of several ten thousand Joule, the drop energy generated is effectively absorbed, protecting the overall construction against damage. The complex development work specially focussed on the attainment of maximum functional reliability and zero maintenance at continuous furnace operation with temperatures of several thousand degrees Celsius. Because downtimes due to damage would cause great losses.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.