Experience and Expertise: Solutions for the Oil and Gas Industry

Specially designed friction springs for the effective thrust damping in deep-drilling tools, locking devices for storage reels on pipeline installation ships, working with high-precision and zero-backlash, or maximally stable steel disk couplings for powerful natural gas compressors: The innovative and tailor-made RINGFEDER® solutions prove to be sustainable and future-proof for a variety of different applications from the oil and gas sector. They do not only master the extreme operational conditions in rough environments, of course they also comply with applicable industrial regulations and standards, e.g. ATEX or special factory standards – for the maximum user benefit in terms of reliability, functionality and safety.

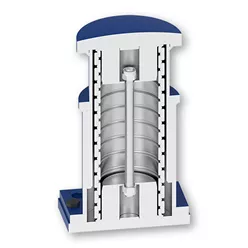

Highly Robust Steel Disk Coupling for Gas Compressors

In order to sustainably cover the ever-increasing global energy demand, gas fields are tapped in more and more remote areas. From there, the gas extracted is either transported via pipelines, or in liquefied form, by means of tankers via sea routes directly to the customers or to processing facilities. In both cases, powerful gas compressors are used before the transport takes place. Torsionally rigid, non-switching steel disk couplings of the RINGFEDER® TND series are ideally suited for establishing a stable and reliable drive connection between the motor and compressor, since they fully comply with typical requirements. They are manufactured of 100 % stainless spring steel, highly resistant to extreme temperatures and ensure maximum transmissible torques while providing the ability to compensate axial, radial and angular misalignments. Furthermore, they do not require lubrication and therefore work in a maintenance-free and almost wear-free fashion. Depending on the specific requirement, RINGFEDER® intensively assists its customers in finding the ideal mounting type of the shaft and hub, e.g. via first-class shrink discs or locking assemblies.

Long-Term Stability and Precision on the High Seas

Pipe layers are highly-specifically and extensively equipped working ships for the laying of underwater pipelines on the sea floor, which later on serve to transport crude oil or natural gas. In the storage winches of one of the largest pipe layers worldwide, top-quality RINGFEDER® precision locking assemblies of the RfN 7015.0 are used. There they establish a zero backlash connection between the drive shaft of the winch and the winch drum and consistently reliably transmit the torque required as well as potential axial loads. In particular due to their property of self-centring, the locking assemblies selected also meet the sophisticated requirements with regard to the concentricity of the components used. The double-sided direction of rotation of the cable drum causes an extreme alternating strain in the long term, which can be permanently mastered by the powerful RINGFEDER® locking devices.

Friction Springs for Effective Thrust Absorption

In intensive cooperation with a globally leading manufacturer of drilling systems and drilling components, which are predominately used in the field of deep drilling for the extraction of crude oil and natural gas storage facilities, RINGFEDER® has implemented a tailor-made special solution. Depending on the performance of the drilling tools used, they potentially get stuck in the subsurface if its condition exceeds a certain degree of hardness or softness. In order to release such a blockage again, a pneumatically driven internal hammer drill works against the drilling tool. A RINGFEDER® friction spring specially designed for this purpose serves as a high-performance damping element which effectively absorbs thrusts and, in this way, reliably protects the drilling tool against tremendously costly damage and failures – and it is absolutely maintenance- and repair-free.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.