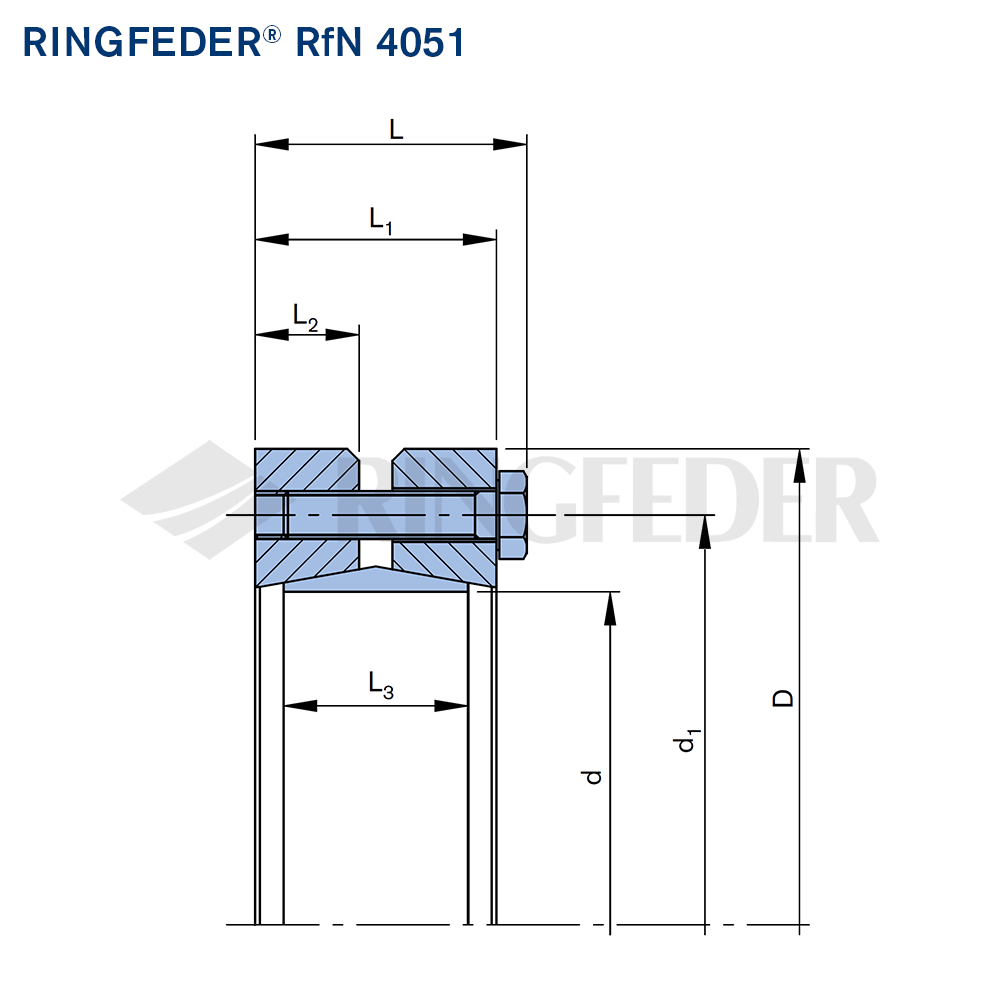

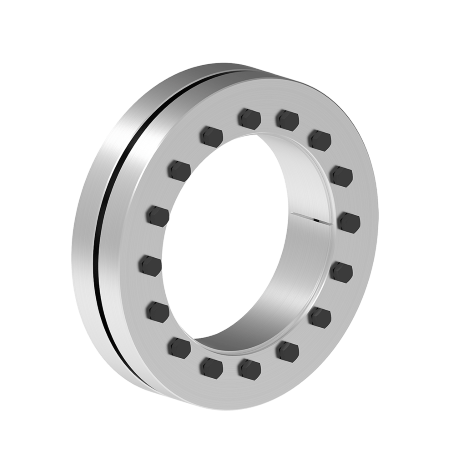

Shrink Discs RfN 4051

Lighter version for moderate transfer values – particularly suited for thin hubs and hollow shafts

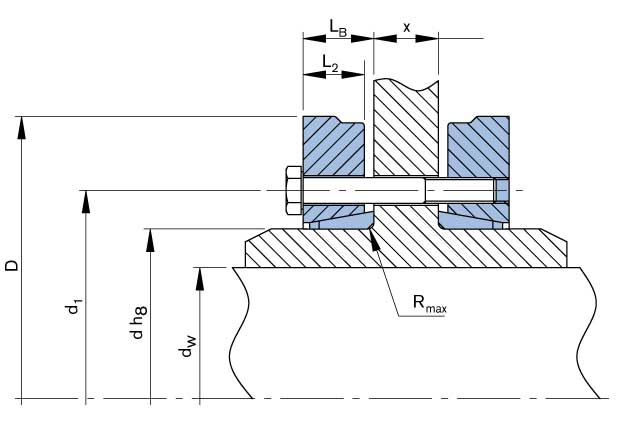

The RINGFEDER® RfN 4051 is a three-part shrink disc and serves to transfer low to moderate torque. The narrow pressure rings require only a very small space. The transferrable torque can be set in a targeted manner for the corresponding application by changing the screw tightening torque.

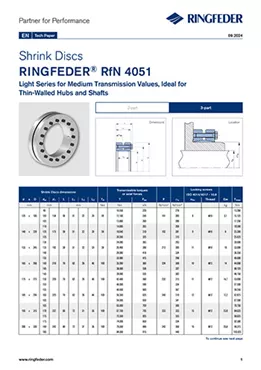

Technical Data & CAD Models

| CAD |

d

mm |

D

mm |

dw

mm |

d1

mm |

L

mm |

L1

mm |

L3

mm |

T

Nm |

P

N/mm2 |

nSc

Stück |

DG

mm |

TA

Nm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

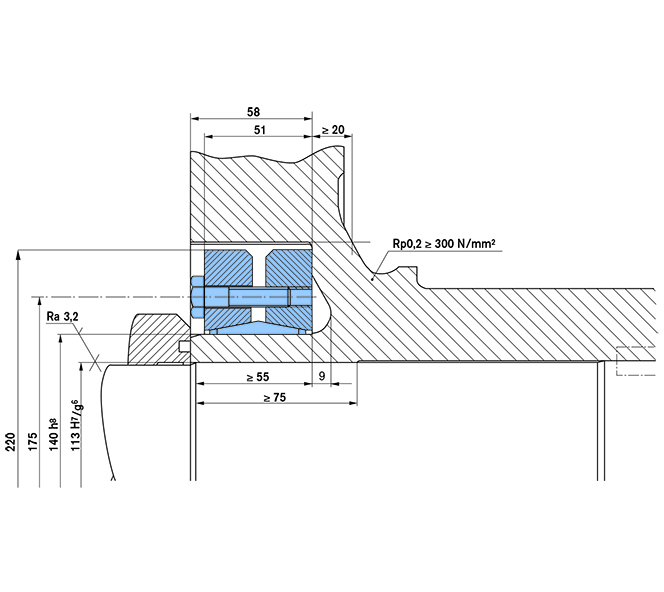

| 125 | 185 | 95 | 158 | 58 | 51 | 39 | 10550 | 191 | 8 | 10 | 59 | |

| 125 | 185 | 100 | 158 | 58 | 51 | 39 | 12100 | 191 | 8 | 10 | 59 | |

| 125 | 185 | 105 | 158 | 58 | 51 | 39 | 13800 | 191 | 8 | 10 | 59 | |

| 140 | 220 | 110 | 175 | 58 | 51 | 39 | 14800 | 192 | 9 | 10 | 59 | |

| 140 | 220 | 120 | 175 | 58 | 51 | 39 | 18640 | 192 | 9 | 10 | 59 | |

| 140 | 220 | 125 | 175 | 58 | 51 | 39 | 20500 | 192 | 9 | 10 | 59 | |

| 155 | 245 | 130 | 192 | 58 | 51 | 39 | 24000 | 212 | 11 | 10 | 59 | |

| 155 | 245 | 135 | 192 | 58 | 51 | 39 | 26400 | 212 | 11 | 10 | 59 | |

| 155 | 245 | 140 | 192 | 58 | 51 | 39 | 29000 | 212 | 11 | 10 | 59 | |

| 165 | 260 | 135 | 210 | 70 | 62 | 46 | 32000 | 224 | 10 | 12 | 100 | |

| 165 | 260 | 140 | 210 | 70 | 62 | 46 | 35200 | 224 | 10 | 12 | 100 | |

| 165 | 260 | 145 | 210 | 70 | 62 | 46 | 38500 | 224 | 10 | 12 | 100 | |

| 175 | 275 | 145 | 220 | 70 | 62 | 46 | 39000 | 232 | 11 | 12 | 100 | |

| 175 | 275 | 150 | 220 | 70 | 62 | 46 | 42400 | 232 | 11 | 12 | 100 | |

| 175 | 275 | 155 | 220 | 70 | 62 | 46 | 46000 | 232 | 11 | 12 | 100 | |

| 185 | 295 | 155 | 225 | 70 | 62 | 46 | 46600 | 240 | 12 | 12 | 100 | |

| 185 | 295 | 160 | 225 | 70 | 62 | 46 | 50300 | 240 | 12 | 12 | 100 | |

| 185 | 295 | 165 | 225 | 70 | 62 | 46 | 54000 | 240 | 12 | 12 | 100 | |

| 195 | 315 | 165 | 237 | 80 | 72 | 56 | 63000 | 233 | 15 | 12 | 100 | |

| 195 | 315 | 170 | 237 | 80 | 72 | 56 | 67700 | 233 | 15 | 12 | 100 | |

| 195 | 315 | 175 | 237 | 80 | 72 | 56 | 72500 | 233 | 15 | 12 | 100 | |

| 200 | 330 | 175 | 242 | 80 | 72 | 56 | 74000 | 243 | 16 | 12 | 100 | |

| 200 | 330 | 180 | 242 | 80 | 72 | 56 | 79500 | 243 | 16 | 12 | 100 | |

| 200 | 330 | 185 | 242 | 80 | 72 | 56 | 84500 | 243 | 16 | 12 | 100 | |

| 220 | 345 | 180 | 265 | 94 | 84 | 66 | 82800 | 220 | 10 | 16 | 250 | |

| 220 | 345 | 190 | 265 | 94 | 84 | 66 | 93500 | 220 | 10 | 16 | 250 | |

| 220 | 345 | 200 | 265 | 94 | 84 | 66 | 105000 | 220 | 10 | 16 | 250 | |

| 240 | 370 | 200 | 290 | 94 | 84 | 66 | 113000 | 243 | 12 | 16 | 250 | |

| 240 | 370 | 210 | 290 | 94 | 84 | 66 | 127500 | 243 | 12 | 16 | 250 | |

| 240 | 370 | 215 | 290 | 94 | 84 | 66 | 134500 | 243 | 12 | 16 | 250 | |

| 260 | 395 | 220 | 310 | 102 | 92 | 72 | 149000 | 240 | 14 | 16 | 250 | |

| 260 | 395 | 230 | 310 | 102 | 92 | 72 | 165000 | 240 | 14 | 16 | 250 | |

| 260 | 395 | 235 | 310 | 102 | 92 | 72 | 173000 | 240 | 14 | 16 | 250 | |

| 280 | 425 | 230 | 333 | 114 | 104 | 84 | 171000 | 218 | 16 | 16 | 250 | |

| 280 | 425 | 240 | 333 | 114 | 104 | 84 | 189000 | 218 | 16 | 16 | 250 | |

| 280 | 425 | 250 | 333 | 114 | 104 | 84 | 208000 | 218 | 16 | 16 | 250 | |

| 300 | 460 | 250 | 358 | 114 | 104 | 84 | 215000 | 229 | 18 | 16 | 250 | |

| 300 | 460 | 260 | 358 | 114 | 104 | 84 | 234000 | 229 | 18 | 16 | 250 | |

| 300 | 460 | 270 | 358 | 114 | 104 | 84 | 255000 | 229 | 18 | 16 | 250 | |

| 320 | 495 | 270 | 378 | 116 | 106 | 84 | 260000 | 239 | 20 | 16 | 250 | |

| 320 | 495 | 280 | 378 | 116 | 106 | 84 | 284000 | 239 | 20 | 16 | 250 | |

| 320 | 495 | 290 | 378 | 116 | 106 | 84 | 306000 | 239 | 20 | 16 | 250 | |

| 340 | 535 | 290 | 402 | 116 | 106 | 84 | 300000 | 236 | 21 | 16 | 250 | |

| 340 | 535 | 300 | 402 | 116 | 106 | 84 | 324000 | 236 | 21 | 16 | 250 | |

| 340 | 535 | 305 | 402 | 116 | 106 | 84 | 337000 | 236 | 21 | 16 | 250 | |

| 350 | 545 | 300 | 413 | 135 | 122 | 100 | 372000 | 230 | 16 | 20 | 490 | |

| 350 | 545 | 305 | 413 | 135 | 122 | 100 | 385000 | 230 | 16 | 20 | 490 | |

| 350 | 545 | 310 | 413 | 135 | 122 | 100 | 400000 | 230 | 16 | 20 | 490 | |

| 360 | 555 | 300 | 423 | 135 | 122 | 100 | 360000 | 223 | 16 | 20 | 490 | |

| 360 | 555 | 310 | 423 | 135 | 122 | 100 | 388000 | 223 | 16 | 20 | 490 | |

| 360 | 555 | 320 | 423 | 135 | 122 | 100 | 415000 | 223 | 16 | 20 | 490 | |

| 380 | 585 | 320 | 442 | 149 | 136 | 112 | 435000 | 213 | 18 | 20 | 490 | |

| 380 | 585 | 325 | 442 | 149 | 136 | 112 | 451000 | 213 | 18 | 20 | 490 | |

| 380 | 585 | 330 | 442 | 149 | 136 | 112 | 467000 | 213 | 18 | 20 | 490 | |

| 390 | 595 | 330 | 452 | 149 | 136 | 112 | 505000 | 230 | 20 | 20 | 490 | |

| 390 | 595 | 340 | 452 | 149 | 136 | 112 | 540000 | 230 | 20 | 20 | 490 | |

| 390 | 595 | 350 | 452 | 149 | 136 | 112 | 577000 | 230 | 20 | 20 | 490 | |

| 400 | 615 | 340 | 462 | 149 | 136 | 112 | 550000 | 236 | 21 | 20 | 490 | |

| 400 | 615 | 350 | 462 | 149 | 136 | 112 | 587000 | 236 | 21 | 20 | 490 | |

| 400 | 615 | 360 | 462 | 149 | 136 | 112 | 626000 | 236 | 21 | 20 | 490 | |

| 420 | 630 | 350 | 485 | 157 | 144 | 120 | 578000 | 219 | 22 | 20 | 490 | |

| 420 | 630 | 360 | 485 | 157 | 144 | 120 | 617000 | 219 | 22 | 20 | 490 | |

| 420 | 630 | 370 | 485 | 157 | 144 | 120 | 655000 | 219 | 22 | 20 | 490 | |

| 440 | 660 | 370 | 505 | 157 | 144 | 120 | 677000 | 229 | 24 | 20 | 490 | |

| 440 | 660 | 380 | 505 | 157 | 144 | 120 | 719000 | 229 | 24 | 20 | 490 | |

| 440 | 660 | 390 | 505 | 157 | 144 | 120 | 762000 | 229 | 24 | 20 | 490 | |

| 460 | 685 | 390 | 527 | 171 | 158 | 132 | 840000 | 232 | 28 | 20 | 490 | |

| 460 | 685 | 400 | 527 | 171 | 158 | 132 | 890000 | 232 | 28 | 20 | 490 | |

| 460 | 685 | 410 | 527 | 171 | 158 | 132 | 935000 | 232 | 28 | 20 | 490 | |

| 480 | 715 | 410 | 547 | 171 | 158 | 132 | 891000 | 222 | 28 | 20 | 490 | |

| 480 | 715 | 420 | 547 | 171 | 158 | 132 | 941000 | 222 | 28 | 20 | 490 | |

| 480 | 715 | 425 | 547 | 171 | 158 | 132 | 966000 | 222 | 28 | 20 | 490 | |

| 500 | 750 | 425 | 567 | 171 | 158 | 132 | 986000 | 228 | 30 | 20 | 490 | |

| 500 | 750 | 430 | 567 | 171 | 158 | 132 | 1013000 | 228 | 30 | 20 | 490 | |

| 500 | 750 | 440 | 567 | 171 | 158 | 132 | 1066000 | 228 | 30 | 20 | 490 |

| CAD |

d inch |

D inch |

dw inch |

d1 inch |

L inch |

L1 inch |

L3 inch |

T ft-lbs |

P psi |

nSc pcs. |

DG mm |

TA ft-lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.921 | 7.283 | 3.740 | 6.220 | 2.283 | 2.008 | 1.535 | 7781 | 27723 | 8 | M10 | 45 | |

| 4.921 | 7.283 | 3.937 | 6.220 | 2.283 | 2.008 | 1.535 | 8925 | 27723 | 8 | M10 | 45 | |

| 4.921 | 7.283 | 4.134 | 6.220 | 2.283 | 2.008 | 1.535 | 10178 | 27723 | 8 | M10 | 45 | |

| 5.512 | 8.661 | 4.331 | 6.890 | 2.283 | 2.008 | 1.535 | 10916 | 27868 | 9 | M10 | 45 | |

| 5.512 | 8.661 | 4.724 | 6.890 | 2.283 | 2.008 | 1.535 | 13748 | 27868 | 9 | M10 | 45 | |

| 5.512 | 8.661 | 4.921 | 6.890 | 2.283 | 2.008 | 1.535 | 15120 | 27868 | 9 | M10 | 45 | |

| 6.102 | 9.646 | 5.118 | 7.559 | 2.283 | 2.008 | 1.535 | 17702 | 30771 | 11 | M10 | 45 | |

| 6.102 | 9.646 | 5.315 | 7.559 | 2.283 | 2.008 | 1.535 | 19472 | 30771 | 11 | M10 | 45 | |

| 6.102 | 9.646 | 5.512 | 7.559 | 2.283 | 2.008 | 1.535 | 21390 | 30771 | 11 | M10 | 45 | |

| 6.496 | 10.236 | 5.709 | 8.268 | 2.756 | 2.441 | 1.811 | 28396 | 32512 | 10 | M12 | 75 | |

| 6.496 | 10.236 | 5.512 | 8.268 | 2.756 | 2.441 | 1.811 | 25962 | 32512 | 10 | M12 | 75 | |

| 6.496 | 10.236 | 5.315 | 8.268 | 2.756 | 2.441 | 1.811 | 23602 | 32512 | 10 | M12 | 75 | |

| 6.890 | 10.827 | 6.102 | 8.661 | 2.756 | 2.441 | 1.811 | 33928 | 33674 | 11 | M12 | 75 | |

| 6.890 | 10.827 | 5.709 | 8.661 | 2.756 | 2.441 | 1.811 | 28765 | 33674 | 11 | M12 | 75 | |

| 6.890 | 10.827 | 5.906 | 8.661 | 2.756 | 2.441 | 1.811 | 31273 | 33674 | 11 | M12 | 75 | |

| 7.283 | 11.614 | 6.496 | 8.858 | 2.756 | 2.441 | 1.811 | 39829 | 34835 | 12 | M12 | 75 | |

| 7.283 | 11.614 | 6.299 | 8.858 | 2.756 | 2.441 | 1.811 | 37100 | 34835 | 12 | M12 | 75 | |

| 7.283 | 11.614 | 6.102 | 8.858 | 2.756 | 2.441 | 1.811 | 34371 | 34835 | 12 | M12 | 75 | |

| 7.677 | 12.402 | 6.890 | 9.331 | 3.150 | 2.835 | 2.205 | 53474 | 33819 | 15 | M12 | 75 | |

| 7.677 | 12.402 | 6.693 | 9.331 | 3.150 | 2.835 | 2.205 | 49933 | 33819 | 15 | M12 | 75 | |

| 7.677 | 12.402 | 6.496 | 9.331 | 3.150 | 2.835 | 2.205 | 46467 | 33819 | 15 | M12 | 75 | |

| 7.874 | 12.992 | 7.283 | 9.528 | 3.150 | 2.835 | 2.205 | 62325 | 35270 | 16 | M12 | 75 | |

| 7.874 | 12.992 | 6.890 | 9.528 | 3.150 | 2.835 | 2.205 | 54580 | 35270 | 16 | M12 | 75 | |

| 7.874 | 12.992 | 7.087 | 9.528 | 3.150 | 2.835 | 2.205 | 58637 | 35270 | 16 | M12 | 75 | |

| 8.661 | 13.583 | 7.874 | 10.433 | 3.701 | 3.307 | 2.598 | 77445 | 31932 | 10 | M16 | 185 | |

| 8.661 | 13.583 | 7.480 | 10.433 | 3.701 | 3.307 | 2.598 | 68963 | 31932 | 10 | M16 | 185 | |

| 8.661 | 13.583 | 7.087 | 10.433 | 3.701 | 3.307 | 2.598 | 61071 | 31932 | 10 | M16 | 185 | |

| 9.449 | 14.567 | 7.874 | 11.417 | 3.701 | 3.307 | 2.598 | 83345 | 35270 | 12 | M16 | 185 | |

| 9.449 | 14.567 | 8.268 | 11.417 | 3.701 | 3.307 | 2.598 | 94040 | 35270 | 12 | M16 | 185 | |

| 9.449 | 14.567 | 8.465 | 11.417 | 3.701 | 3.307 | 2.598 | 99203 | 35270 | 12 | M16 | 185 | |

| 10.236 | 15.551 | 9.252 | 12.205 | 4.016 | 3.622 | 2.835 | 127600 | 34835 | 14 | M16 | 185 | |

| 10.236 | 15.551 | 8.661 | 12.205 | 4.016 | 3.622 | 2.835 | 109898 | 34835 | 14 | M16 | 185 | |

| 10.236 | 15.551 | 9.055 | 12.205 | 4.016 | 3.622 | 2.835 | 121699 | 34835 | 14 | M16 | 185 | |

| 11.024 | 16.732 | 9.843 | 13.110 | 4.488 | 4.094 | 3.307 | 153415 | 31642 | 16 | M16 | 185 | |

| 11.024 | 16.732 | 9.449 | 13.110 | 4.488 | 4.094 | 3.307 | 139401 | 31642 | 16 | M16 | 185 | |

| 11.024 | 16.732 | 9.055 | 13.110 | 4.488 | 4.094 | 3.307 | 126124 | 31642 | 16 | M16 | 185 | |

| 11.811 | 18.110 | 9.843 | 14.094 | 4.488 | 4.094 | 3.307 | 158578 | 33238 | 18 | M16 | 185 | |

| 11.811 | 18.110 | 10.630 | 14.094 | 4.488 | 4.094 | 3.307 | 188080 | 33238 | 18 | M16 | 185 | |

| 11.811 | 18.110 | 10.236 | 14.094 | 4.488 | 4.094 | 3.307 | 172591 | 33238 | 18 | M16 | 185 | |

| 12.598 | 19.488 | 11.417 | 14.882 | 4.567 | 4.173 | 3.307 | 225696 | 34690 | 20 | M16 | 185 | |

| 12.598 | 19.488 | 10.630 | 14.882 | 4.567 | 4.173 | 3.307 | 191768 | 34690 | 20 | M16 | 185 | |

| 12.598 | 19.488 | 11.024 | 14.882 | 4.567 | 4.173 | 3.307 | 209470 | 34690 | 20 | M16 | 185 | |

| 13.386 | 21.063 | 12.008 | 15.827 | 4.567 | 4.173 | 3.307 | 248561 | 34254 | 21 | M16 | 185 | |

| 13.386 | 21.063 | 11.811 | 15.827 | 4.567 | 4.173 | 3.307 | 238973 | 34254 | 21 | M16 | 185 | |

| 13.386 | 21.063 | 11.417 | 15.827 | 4.567 | 4.173 | 3.307 | 221271 | 34254 | 21 | M16 | 185 | |

| 13.780 | 21.457 | 11.811 | 16.260 | 5.315 | 4.803 | 3.937 | 274376 | 33383 | 16 | M20 | 361 | |

| 13.780 | 21.457 | 12.008 | 16.260 | 5.315 | 4.803 | 3.937 | 283964 | 33383 | 16 | M20 | 361 | |

| 13.780 | 21.457 | 12.205 | 16.260 | 5.315 | 4.803 | 3.937 | 295028 | 33383 | 16 | M20 | 361 | |

| 14.173 | 21.850 | 12.598 | 16.654 | 5.315 | 4.803 | 3.937 | 306092 | 32367 | 16 | M20 | 361 | |

| 14.173 | 21.850 | 11.811 | 16.654 | 5.315 | 4.803 | 3.937 | 265525 | 32367 | 16 | M20 | 361 | |

| 14.173 | 21.850 | 12.205 | 16.654 | 5.315 | 4.803 | 3.937 | 286177 | 32367 | 16 | M20 | 361 | |

| 14.961 | 23.031 | 12.992 | 17.402 | 5.866 | 5.354 | 4.409 | 344445 | 30916 | 18 | M20 | 361 | |

| 14.961 | 23.031 | 12.795 | 17.402 | 5.866 | 5.354 | 4.409 | 332644 | 30916 | 18 | M20 | 361 | |

| 14.961 | 23.031 | 12.598 | 17.402 | 5.866 | 5.354 | 4.409 | 320843 | 30916 | 18 | M20 | 361 | |

| 15.354 | 23.425 | 12.992 | 17.795 | 5.866 | 5.354 | 4.409 | 372473 | 33383 | 20 | M20 | 361 | |

| 15.354 | 23.425 | 13.386 | 17.795 | 5.866 | 5.354 | 4.409 | 398288 | 33383 | 20 | M20 | 361 | |

| 15.354 | 23.425 | 13.780 | 17.795 | 5.866 | 5.354 | 4.409 | 425578 | 33383 | 20 | M20 | 361 | |

| 15.748 | 24.213 | 14.173 | 18.189 | 5.866 | 5.354 | 4.409 | 461719 | 34254 | 21 | M20 | 361 | |

| 15.748 | 24.213 | 13.386 | 18.189 | 5.866 | 5.354 | 4.409 | 405664 | 34254 | 21 | M20 | 361 | |

| 15.748 | 24.213 | 13.780 | 18.189 | 5.866 | 5.354 | 4.409 | 432954 | 34254 | 21 | M20 | 361 | |

| 16.535 | 24.803 | 14.567 | 19.094 | 6.181 | 5.669 | 4.724 | 483108 | 31787 | 22 | M20 | 361 | |

| 16.535 | 24.803 | 14.173 | 19.094 | 6.181 | 5.669 | 4.724 | 455081 | 31787 | 22 | M20 | 361 | |

| 16.535 | 24.803 | 13.780 | 19.094 | 6.181 | 5.669 | 4.724 | 426315 | 31787 | 22 | M20 | 361 | |

| 17.323 | 25.984 | 14.567 | 19.882 | 6.181 | 5.669 | 4.724 | 499335 | 33238 | 24 | M20 | 361 | |

| 17.323 | 25.984 | 14.961 | 19.882 | 6.181 | 5.669 | 4.724 | 530313 | 33238 | 24 | M20 | 361 | |

| 17.323 | 25.984 | 15.354 | 19.882 | 6.181 | 5.669 | 4.724 | 562028 | 33238 | 24 | M20 | 361 | |

| 18.110 | 26.969 | 16.142 | 20.748 | 6.732 | 6.220 | 5.197 | 689628 | 33674 | 28 | M20 | 361 | |

| 18.110 | 26.969 | 15.354 | 20.748 | 6.732 | 6.220 | 5.197 | 619559 | 33674 | 28 | M20 | 361 | |

| 18.110 | 26.969 | 15.748 | 20.748 | 6.732 | 6.220 | 5.197 | 656437 | 33674 | 28 | M20 | 361 | |

| 18.898 | 28.150 | 16.535 | 21.535 | 6.732 | 6.220 | 5.197 | 694053 | 32222 | 28 | M20 | 361 | |

| 18.898 | 28.150 | 16.732 | 21.535 | 6.732 | 6.220 | 5.197 | 712493 | 32222 | 28 | M20 | 361 | |

| 18.898 | 28.150 | 16.142 | 21.535 | 6.732 | 6.220 | 5.197 | 657175 | 32222 | 28 | M20 | 361 | |

| 19.685 | 29.528 | 16.732 | 22.323 | 6.732 | 6.220 | 5.197 | 727244 | 33093 | 30 | M20 | 361 | |

| 19.685 | 29.528 | 16.929 | 22.323 | 6.732 | 6.220 | 5.197 | 747158 | 33093 | 30 | M20 | 361 | |

| 19.685 | 29.528 | 17.323 | 22.323 | 6.732 | 6.220 | 5.197 | 786250 | 33093 | 30 | M20 | 361 |

Images & Drawings

Product Characteristics

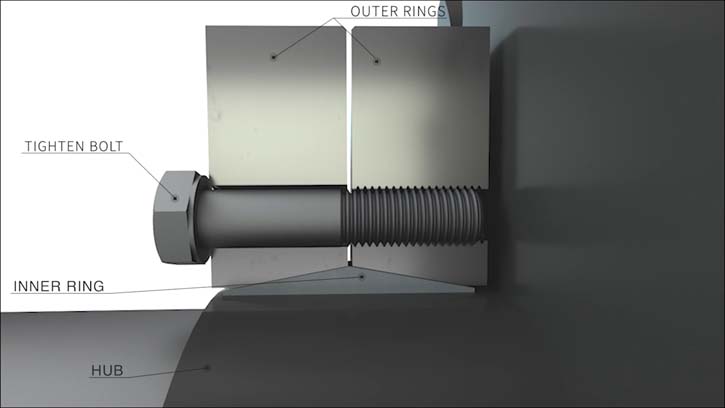

Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances and fine surface finishes, they also need considerable effort with mounting and removal. The shrink disc connection has none of these disadvantages and is better than any of the other usual connection methods with regard to fatigue strength under alternating torsional stress.

- Light design – suitable for middle transmissible values when space is limited.

- Compensation of small tolerance errors – please contact our engineers.

- Maximum reliability – suitable for static, dynamic and impact loads.

- Slitted inner ring – low forces and pressures on hub and shaft.

- Simplified manufacture – only plain shaft and bore diameters with easily achieved surface finish and tolerances are required.

- Easy mounting – no steps, keyways, splines are required, therefore hubs can be located and locked at any point or angle on the shaft. RINGFEDER® Shrink Discs use standard screws tightened with standard tools. No additional machining or fitting work is required.

- Easy replacement – the RINGFEDER® shrink disc is free from any form fit.

- Low susceptibility to contamination – when the locking screws are tightened the functional contact surfaces are pressed firmly together and prevent the ingress of dirt and moisture.

Shrink discs GT (split)

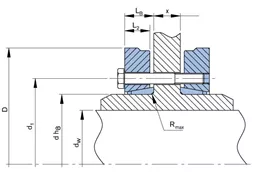

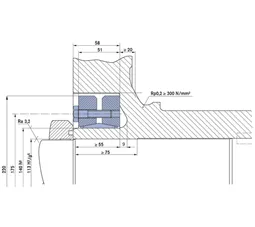

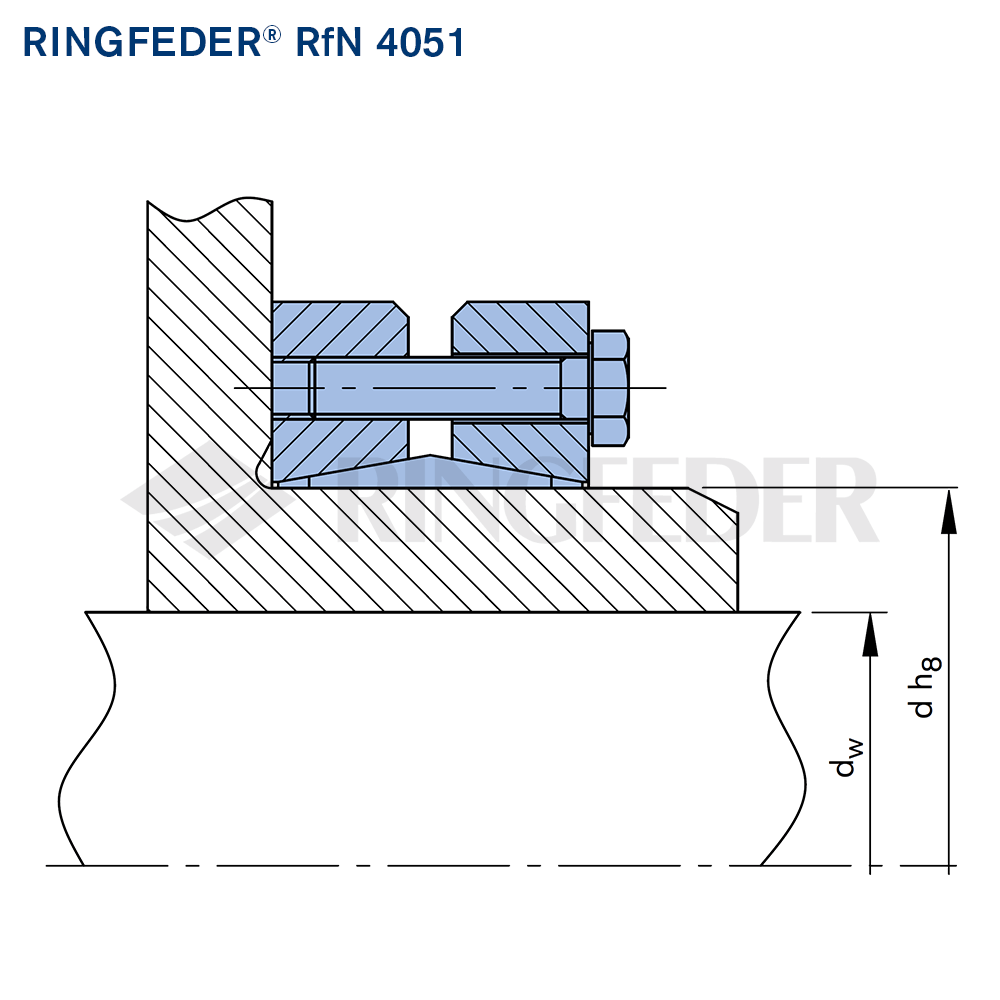

In the application shown special screws according to the dimension X are required, which have to be ordered accordingly. When dimension „X“ larger than 2 · L1 (RfN 4051 Light Duty Series) is chosen, a reduction of the transmissible torque up to 50% has to be considered to the type GT.

Surface finishes

For shaft diameter dw: Peak-to-valley height Ra ≤ 3,2 μm.

Tolerances

For shaft h9

Downloads

Product Paper RINGFEDER® Shrink Discs

Tech Paper Shrink Discs RINGFEDER® RfN 4051

Instruction Manual Shrink Discs RINGFEDER® RfN 4051, RfN 4061, RfN 4071, RfN 4073, RfN 4091

Further downloads including certificates, instruction manuals and product images are available to you in our Download Center:

DownloadsSuitable Industry Solutions

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.