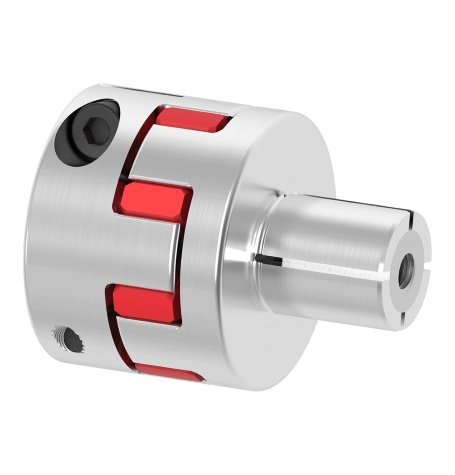

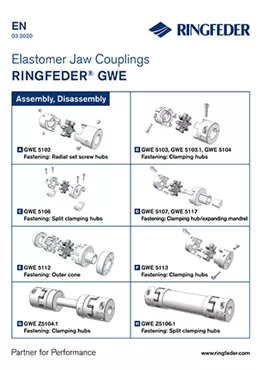

Elastomer Jaw Couplings GWE 5117

Torsionally flexible, backlash-free elastomer coupling of highly compact design with single-slit aluminium clamping hubs as well as expanding mandrel and inner cone made of steel for friction-locked torque transmission on hollow shafts.

- 5 different sizes

- Bore Diameter d: 4-35 mm (0.157-1.378 inch)

- Outer Diameter D: 24.5-64.5 mm (0.966-2.539 inch)

- Overall Length L: 42-82 mm (1.654-3.228 inch)

- Rotational Speed nmax: 6,000-15,000 1/min

- Torque T: 3-160 Nm (2.21 to 118.01 ft·lb)

Product Characteristics

Your Benefits

Backlash-free elastomer jaw couplings of the RINGFEDER® GWE series are the optimum solution for all drive tasks requiring extraordinary positioning accuracy as well as highly effective damping of shocks and vibrations. They effectively compensate for radial, axial and angular shaft misalignments, are axially pluggable, puncture-proof and electrically insulating.

The new type RINGFEDER® GWE 5117 is equipped with aluminium clamping hubs as well as an expanding mandrel and inner cone made of steel for friction-locked power transmission on hollow shafts. It is particularly convincing due to:

- Low masses – thanks to specially optimized hubs made of high-quality aluminum.

- Superior concentricity as well as uniform, vibration- and shock-damped power transmission – due to highest manufacturing precision, symmetrical arrangement of clamping slots and screw positions as well as unslotted cam area.

- Convenient application even in very small, confined spaces – because of its extremely compact, short design with minimal moment of inertia.

- Highly precise, absolutely backlash-free torque transmission – from 3 to 160 Newton meters (2.21 to 118.01 ft·lb).

- Optimum availability – in a total of five sizes with a wide bore diameter range from 4 to 35 millimeters (0.157 to 1.378 inch), at an attractive price and in short delivery times.

- Adjustment of misalignment capability, damping behavior and torsional stiffness as required – by means of bored and unbored elastomer spiders of four different Shore hardnesses, from 80 SH A to 64 SH D.*

- Coupling hubs with keyways if needed – according to DIN 6885-1 or standard inch dimensions.

- Unambiguous identification and simplified handling – thanks to obligatory laser marking that includes type designation, date of manufacture as well as screw tightening torques according to international and Anglo-American system of units.

- Maximum operational safety in explosion-endangered areas – thanks to optional compliance with ATEX according to Product Directive 2014/34/EU and DIN EN ISO 80079-36:2016 if required.

* As standard, all coupling sizes of the RINGFEDER® GWE 5117 type are equipped with a media-resistant red elastomer spider made of high-quality polyurethane with a Shore hardness of 98 SH A.

Ideal for Many Applications

- Linear Technology and Motion Control Systems

- Measuring Equipment and Control Technology

- Test Benches

- Precision Drives

- Feed Drives

- Grinding and Milling Spindles

- Machine Tools

- Packing Machines

- Robotics

- Transfer Lines

- Multi-Spindle Heads

- Wood Processing Equipment

- Textile Machinery

- Conveying Equipment

Technical Explanations

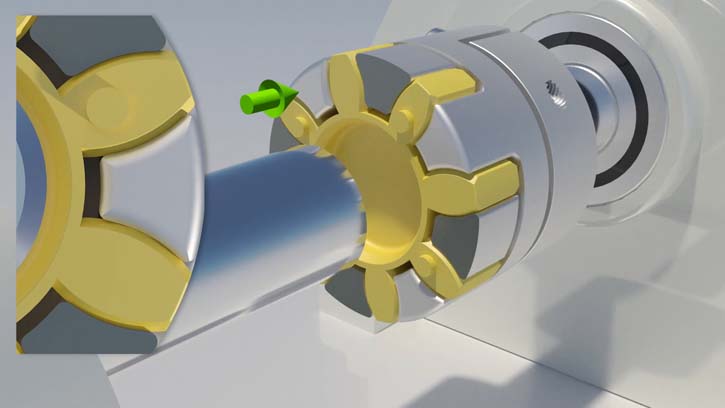

Each hub of the elastomer jaw couplings of the RINGFEDER® GWE series has concave claws on its face side. The essential functions of the coupling, i.e. to transmit torque and to absorb shocks as well as to compensate for unavoidable shaft misalignments, is enabled by plugging two hubs together and filling the resulting free space with an elastomeric spider. In order to achieve a high positioning accuracy also in reverse operation, all types of the GWE series are backlash-free. This freedom from backlash of the couplings results from the pressure pre-tensioning of the elastomeric spider. Due to the different Shore hardnesses of the elastomeric spider, which is associated with the couplings' torsional stiffness, it is possible to optimize the entire drive train in terms of rotary oscillation. Detailed information on the technical properties of the elastomeric spiders is given in our "Product Paper & Tech Paper RINGFEDER® Elastomer Jaw Couplings". The shaft tolerance should lie within the fitting tolerance "g6" to "h7".

Your Contact

You have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. Contact us quickly and easily via our request form, by e-mail or telephone.

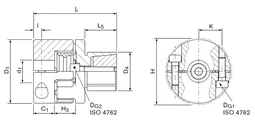

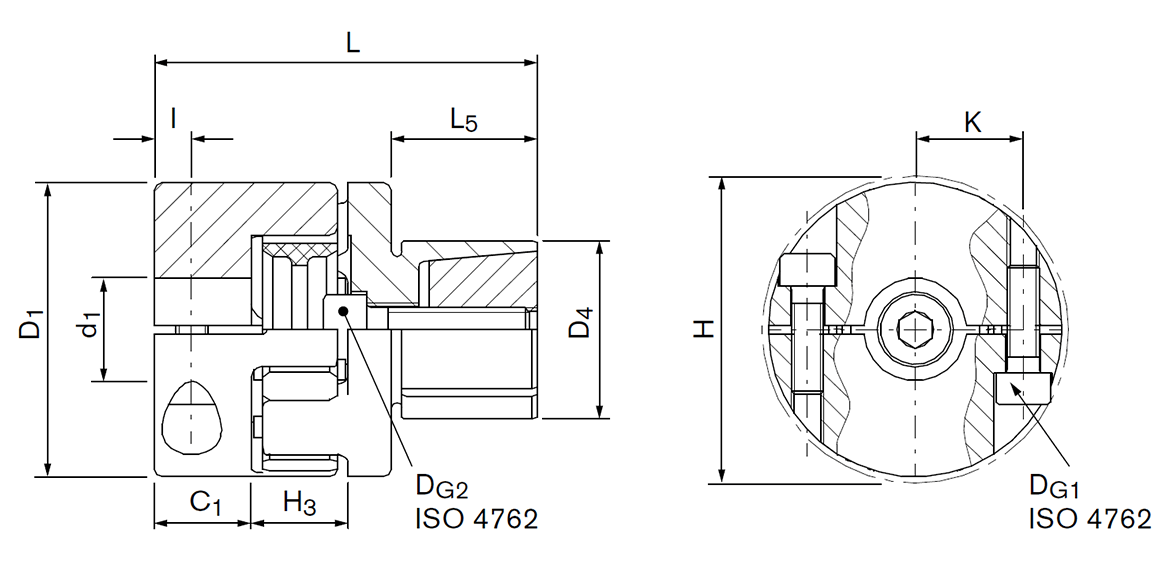

Images & Drawings

Technical Data & CAD Models

| CAD |

Größe/Size

|

d1min

mm |

d1max

mm |

D1

mm |

D4 min

mm |

H

mm |

L

mm |

L5

mm |

T

Nm |

nmax

1/min |

TA1

Nm |

TA2

Nm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 12 | 4 | 12 | 24,5 | 10 | 26 | 42 | 12 | 9 | 15000 | 2,1 | 4 | |

| 14 | 5 | 15 | 29,5 | 13 | 33 | 47,5 | 20 | 12,5 | 13000 | 5 | 9 | |

| 19 | 8 | 20 | 39,5 | 14 | 45 | 65,5 | 25 | 17 | 10000 | 14 | 12 | |

| 24 | 10 | 32 | 54,5 | 23 | 57 | 71 | 27 | 60 | 7000 | 15 | 32 | |

| 28 | 14 | 35 | 64,5 | 26 | 68 | 82 | 32 | 160 | 6000 | 35 | 60 |

| CAD |

Größe/Size |

d1min inch |

d1max inch |

C1 inch |

D1 inch |

D4 min inch |

H inch |

H3 inch |

L inch |

L5 inch |

T ft-lbs |

nmax rpm |

DG1 mm |

TA1 ft-lbs |

DG2 mm |

TA2 ft-lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 12 | 0.157 | 0.472 | 0.433 | 0.965 | 0.394 | 1.024 | 0.472 | 1.654 | 0.472 | 7 | 15000 | 3 | 1.5 | 4 | 3.0 | |

| 14 | 0.197 | 0.591 | 0.374 | 1.161 | 0.512 | 1.299 | 0.512 | 1.870 | 0.787 | 9 | 13000 | 4 | 3.7 | 5 | 6.6 | |

| 19 | 0.315 | 0.787 | 0.669 | 1.555 | 0.551 | 1.772 | 0.630 | 2.579 | 0.984 | 13 | 10000 | 6 | 10.3 | 6 | 8.9 | |

| 24 | 0.394 | 1.260 | 0.709 | 2.146 | 0.906 | 2.244 | 0.709 | 2.795 | 1.063 | 44 | 7000 | 6 | 11.1 | 8 | 23.6 | |

| 28 | 0.551 | 1.378 | 0.827 | 2.539 | 1.024 | 2.677 | 0.748 | 3.228 | 1.260 | 118 | 6000 | 8 | 25.8 | 10 | 44.3 |

Downloads

Product Paper Elastomer Jaw Couplings RINGFEDER® GWE, TNM, TNS, TNB

Tech Paper Elastomer Jaw Couplings RINGFEDER® GWE 5117

Instruction Manual Elastomer Jaw Couplings RINGFEDER® GWE

Further downloads including certificates, instruction manuals and product images are available to you in our Download Center:

DownloadsRelated RINGFEDER® Industry Solutions