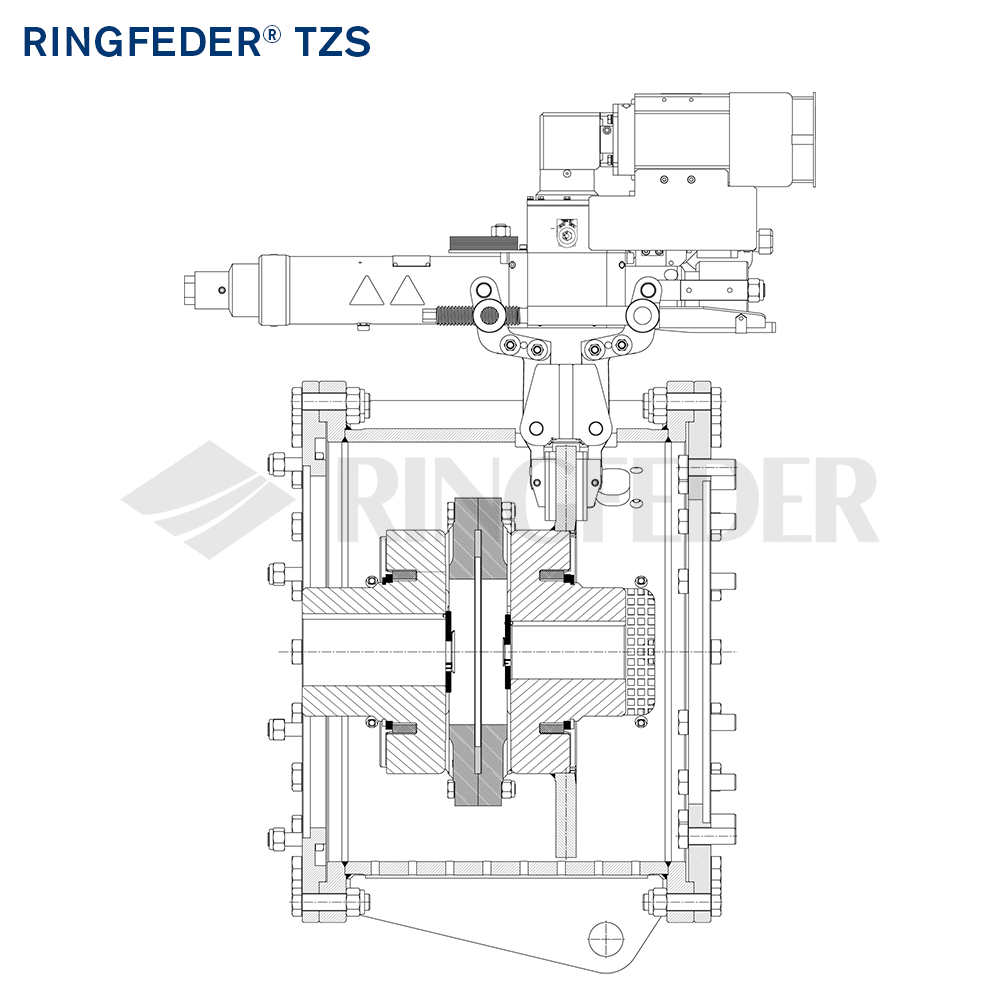

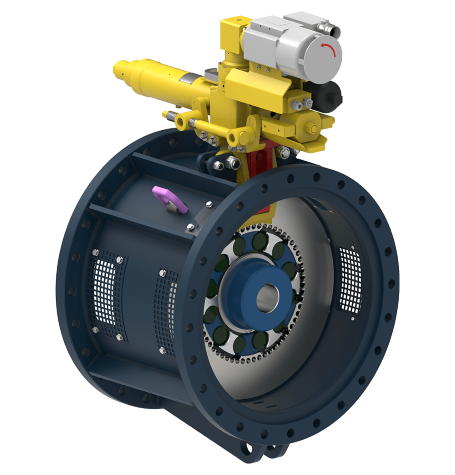

Coupling-Brake Systems TZS

Torsionally flexible Coupling-Brake Systems, modular in design, adaptable to any requirement, and equipped with the robust RINGFEDER® Elastomer Coupling – ensuring highly reliable operation in mining and conveying applications, e.g. in chain and belt conveyors

- Ideally suited for drives of conveying systems in both underground and surface mining, as well as in mechanical and plant engineering, heavy industry, and power transmission technology

- Safe braking and stopping, optionally with the electromechanical function brake TZF EL-SA featuring fail-safe functionality or manual clamping device TZC

- Maximum flexibility and precise customization thanks to a modular system design consisting of coupling, brake disc, brake, cover, and additional options

- Effective shock and vibration damping as well as compensation for axial, radial, and angular shaft misalignment through the integrated RINGFEDER® Elastomer Jaw Coupling

- Design available upon request also in combination with a hydrodynamic coupling

- Auslegung auf Wunsch und Bedarf auch in Verbindung mit hydrodynamischer Kupplung möglich

- ATEX compliance according to Product Directive 2014/34/EU and DIN EN ISO 80079-36:2016 for maximum safety in explosion-endangered areas

Product Characteristics

Your Benefits

The torsionally flexible, individually configurable Coupling-Brake Systems RINGFEDER® TZS – developed and continuously advanced from the industrial brake business of the former TÜSCHEN & ZIMMERMANN GMBH & CO. KG – combine the highest safety standards with innovative technology. They integrate couplings, brake discs, flanges, brakes, and various additional options into a powerful, highly reliable overall system. This system not only couples drives efficiently but also brakes them in a controlled and safe manner – even under the most demanding operating conditions typically encountered in mining and bulk material handling.

Coupling-Brake Systems RINGFEDER® TZS are specifically designed for demanding applications at the mechanical interface between motor and gearbox in conveying systems for underground and surface mining, as well as in heavy industry, power transmission technology, and general mechanical and plant engineering. Thanks to the modular system design, coupling, brake, and other components can be precisely and flexibly adapted to the specific application and its associated operational and customer requirements – either as a compact standard unit or as a customized special solution for specific drive or conveying systems.

Superior Functionality

Coupling-Brake Systems RINGFEDER® TZS act as a defined mechanical interface between motor and gearbox, which – in combination with an integrated braking system – reliably decelerates and stops equipment. They fulfill three core functions equally:

- Coupling & Transmitting: Efficient connection of motor and gearbox and optimal transmission of drive power via highly robust elastomer or hydrodynamic couplings

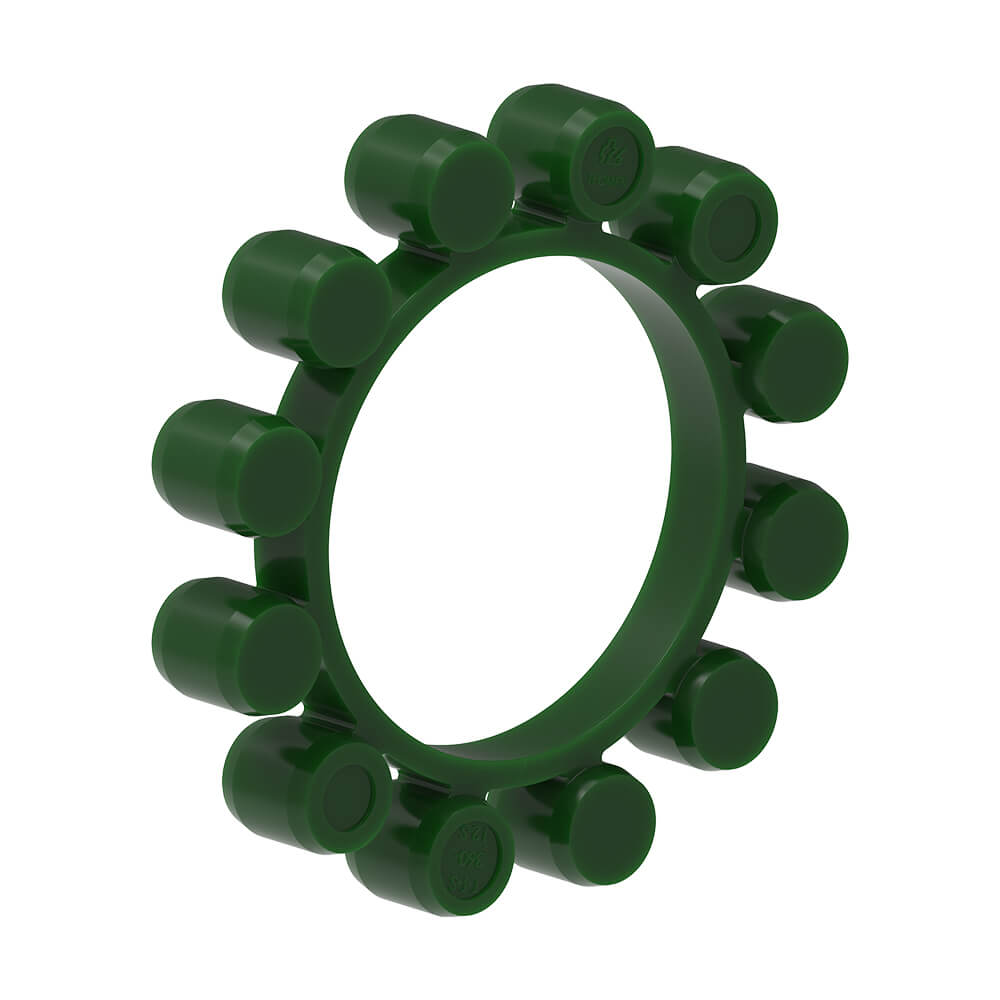

- Damping & Compensating: Effective absorption of shocks, vibrations, and misalignments through durable, wear-resistant, and low-maintenance elastic intermediate rings

- Braking & Holding: Safe braking and constant holding via high-performance brakes and brake discs with optimal heat dissipation

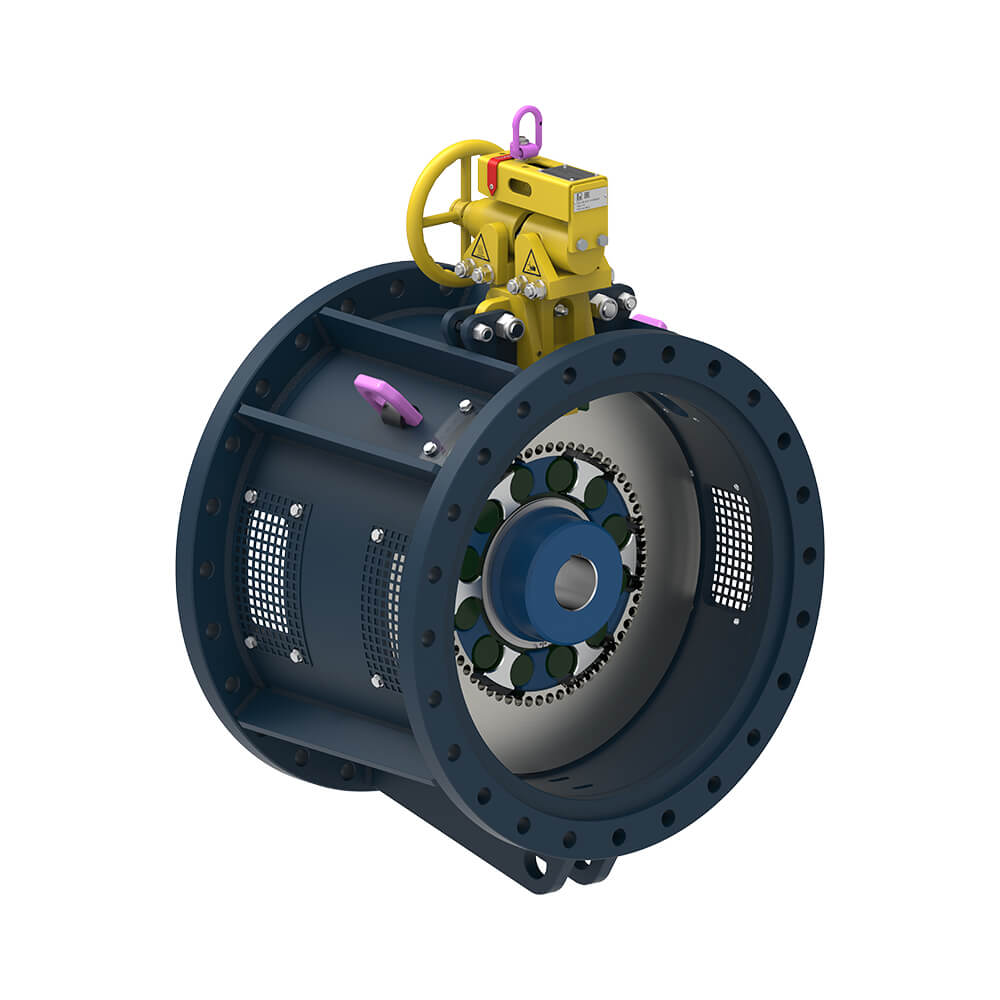

Two Brake System Options

Users can choose between two different brake systems:

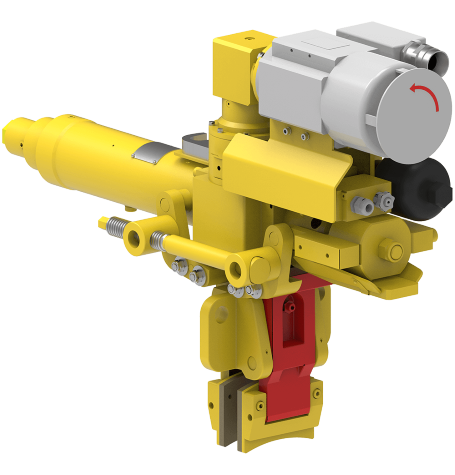

- Electromechanical Function Brake TZF EL-SA

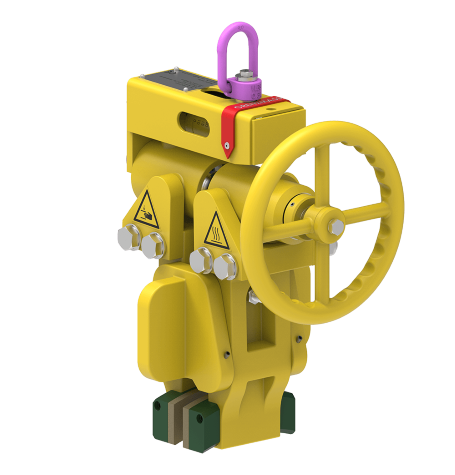

- Manual Clamping Device TZC

The electromechanical function brake TZF EL-SA with fail-safe functionality is electrically actuated and enables controlled braking and holding based on the proven spring-applied principle. This means: The brake is closed in its resting state and pressed securely against the brake disc by stored spring force. It only opens through electrical release – a decisive advantage for operational safety in emergencies or power failures.

The manual clamping device TZC is a hand-operated chain tensioning and locking mechanism for chain scraper conveyors and other drive and conveying systems. It allows safe braking and holding without external power supply and can be mounted directly on the brake cover in any installation position. It is available in two performance classes for different drive capacities.

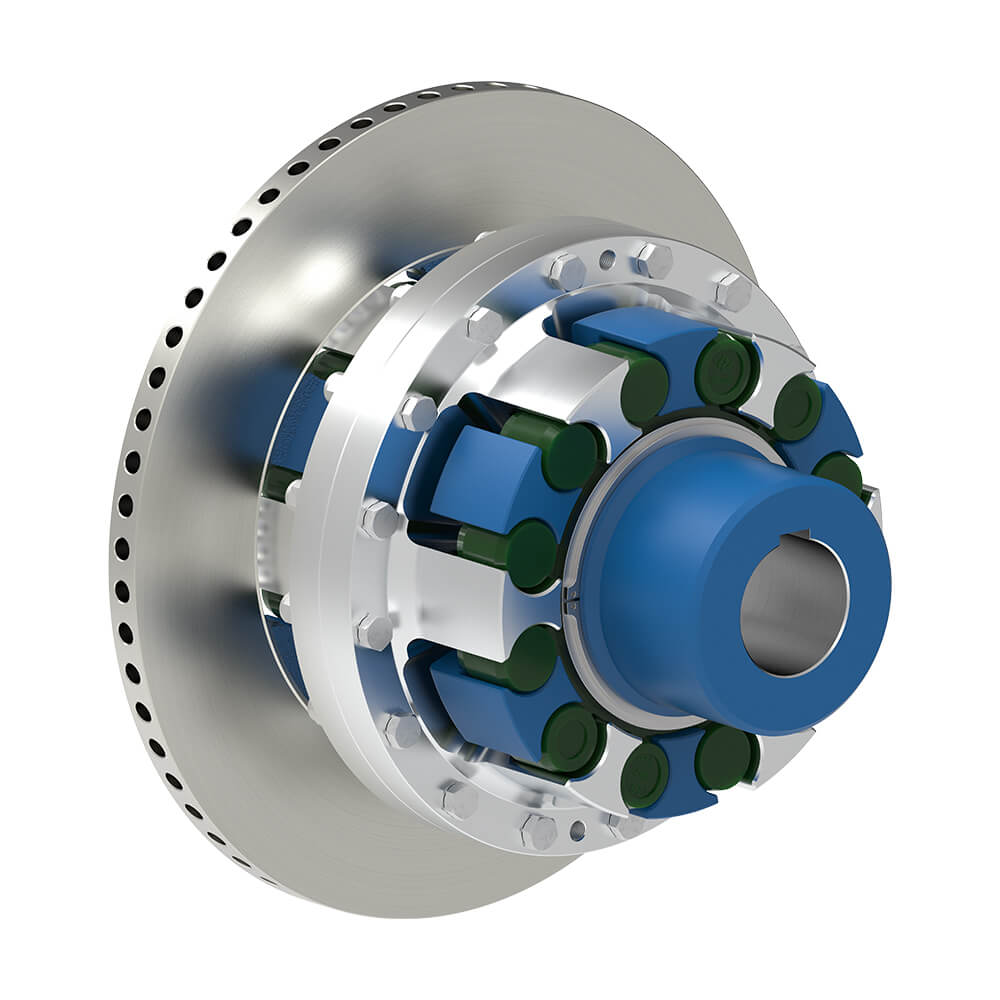

Integrated Elastomer Coupling

The torsionally flexible RINGFEDER® Elastomer Coupling used in the Coupling-Brake Systems RINGFEDER® TZS is fail-safe and movable in all directions. It reliably compensates axial, radial, and angular shaft misalignments caused by assembly inaccuracies or settling effects – thus significantly contributing to the longevity and operational safety of the system. The elastic intermediate ring of the coupling can be replaced radially without shifting the motor, minimizing maintenance and downtime. Drives operating in the oversynchronous range, such as those used in downward conveying systems, particularly benefit from torsionally flexible couplings. Alternatively, for especially smooth acceleration of heavy masses or shock-free motor start-up and ramp-up, connection with a hydrodynamic coupling is also possible.

Modular System Design

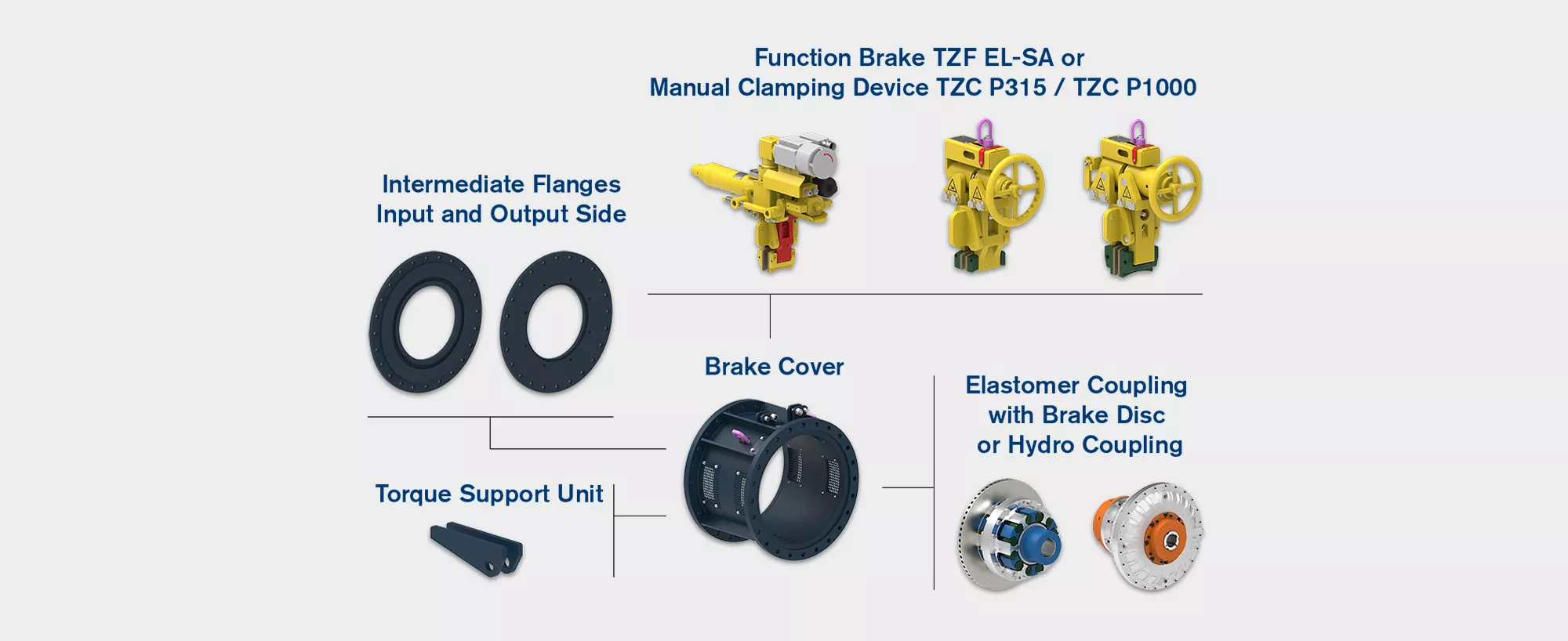

Thanks to the modular design of the Coupling-Brake Systems RINGFEDER® TZS and the associated component kit, users benefit from maximum flexibility and precise adaptation to the specific requirements of their application. All components are freely combinable. The basic configuration consists of the elastomer or hydrodynamic coupling including the required brake disc. The desired brake system – electromechanical functional brake TZF EL-SA based on the spring-applied principle or manual clamping device TZC – is configured with additional components such as cover, flanges, torque support units, and sensors according to customer requirements. This results in tailor-made coupling-brake systems optimally adapted to the specific conditions of the application.

- Adaptable: Ideal, precise solutions for conveying systems, crushers, heavy machinery, and power transmission technology

- Combinable: Coupling, brake disc, brake, cover, and additional options as individual components in a holistic system

- Maintenance-Friendly: Durable, long-life brake linings and easily accessible elastic intermediate rings

- Upgradeable: Additions and extensions, e.g., sensors, can be integrated at any time

- Future-Proof: Uniform system design with long-term spare parts availability

Main Areas of Use

- Conveying systems in underground and surface mining, e.g., chain and belt conveyors

- Heavy industry

- Power transmission technology

- General mechanical and plant engineering

ATEX Compliance

For maximum safety in explosion-endangered areas, Coupling-Brake Systems RINGFEDER® TZS can be supplied in compliance with ATEX according to Product Directive 2014/34/EU and DIN EN ISO 80079-36:2016.

![]()

Images & Drawings

360° Product View

Tap and rotate the XR Model below and experience Coupling-Brake Systems RINGFEDER® TZS in an interactive, touch-enabled 360° Product View. To access full-screen mode on your laptop or desktop device, simply double-click on the product.

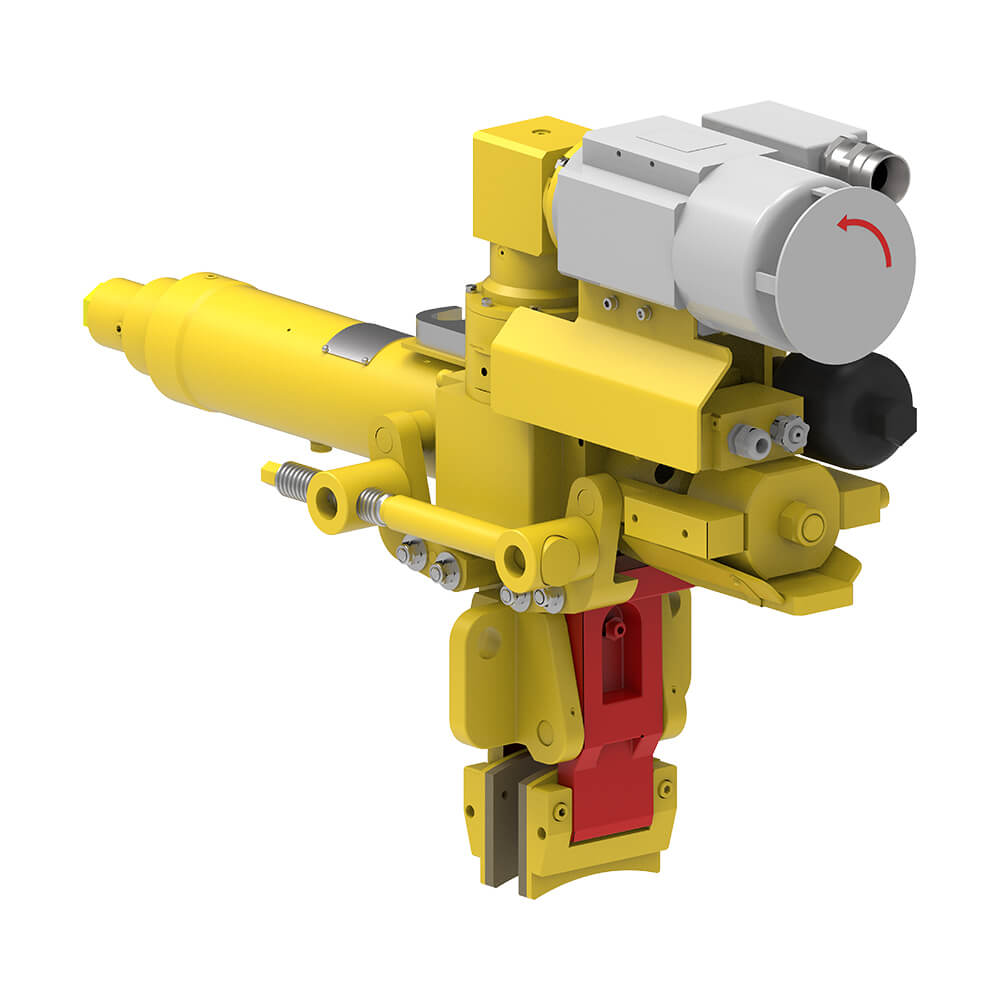

Function Brake TZF EL-SA

The electromechanical Function Brake TZF EL-SA operates on the proven spring-applied principle. It impresses with maximum reliability and its highly compact design, specifically developed for demanding applications in modern conveying and drive systems. It ensures controlled braking and secure holding – thanks to its fail-safe function even in critical emergency situations, such as power failures.

- Electromechanical safety brake based on the spring-applied principle with fail-safe functionality for maximum safety

- Highly compact construction for quick and easy integration into conveying and drive systems, including retrofitting

- Brake release via 400 V or 1000 V electric motor with infinitely adjustable closing time, max. switching voltage: DC 30 V / max. switching current: 2.5 A

- Available for brake disc diameters starting from 480 mm; permissible for circumferential speeds up to 70 m/s

- High-quality manufacturing, wear-resistant and low-maintenance materials, and energy-efficient operation for reduced operating costs

- Explosion protection type "Constructional Safety" ('c') according to EN ISO 80079-37 for maximum safety in explosion-hazardous areas

- Precise position detection through integrated sensors

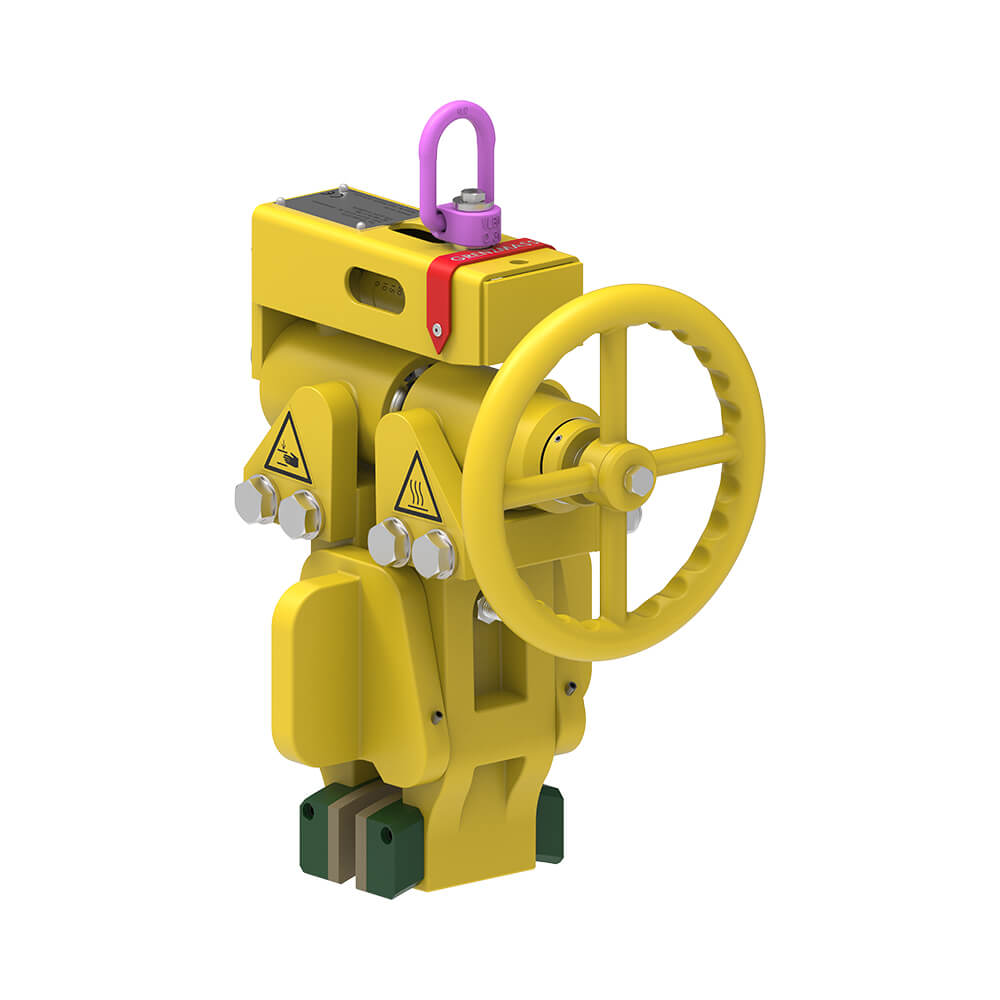

Manual Clamping Device TZC

The proven, highly robust Manual Clamping Devices TZC are hand-operated chain tensioning and locking mechanisms for drive and conveying systems, particularly chain scraper conveyors. They are available in two performance classes and can be mounted directly on the brake cover in any desired installation position. These devices enable safe braking and holding without the need for external power supply.

- Manually operated braking and locking device for secure deceleration and holding without external energy input

- Two performance classes: TZC P315 for drives up to 315 kW, TZC P1000 for drives up to 1000 kW

- Easy handling, fast transport, and flexible on-site installation thanks to highly compact design

- Durable, low-maintenance brake linings made of organic, asbestos-free material – ready for immediate use, gentle on brake discs, and cost-effective

- Individually and flexibly adaptable to various brake disc types and sizes at freely selectable installation position directly on the brake cover

- Explosion protection type "Constructional Safety" ('c') according to EN ISO 80079-37 for maximum safety in explosion-hazardous areas

- Precise position detection via optionally integrated sensors

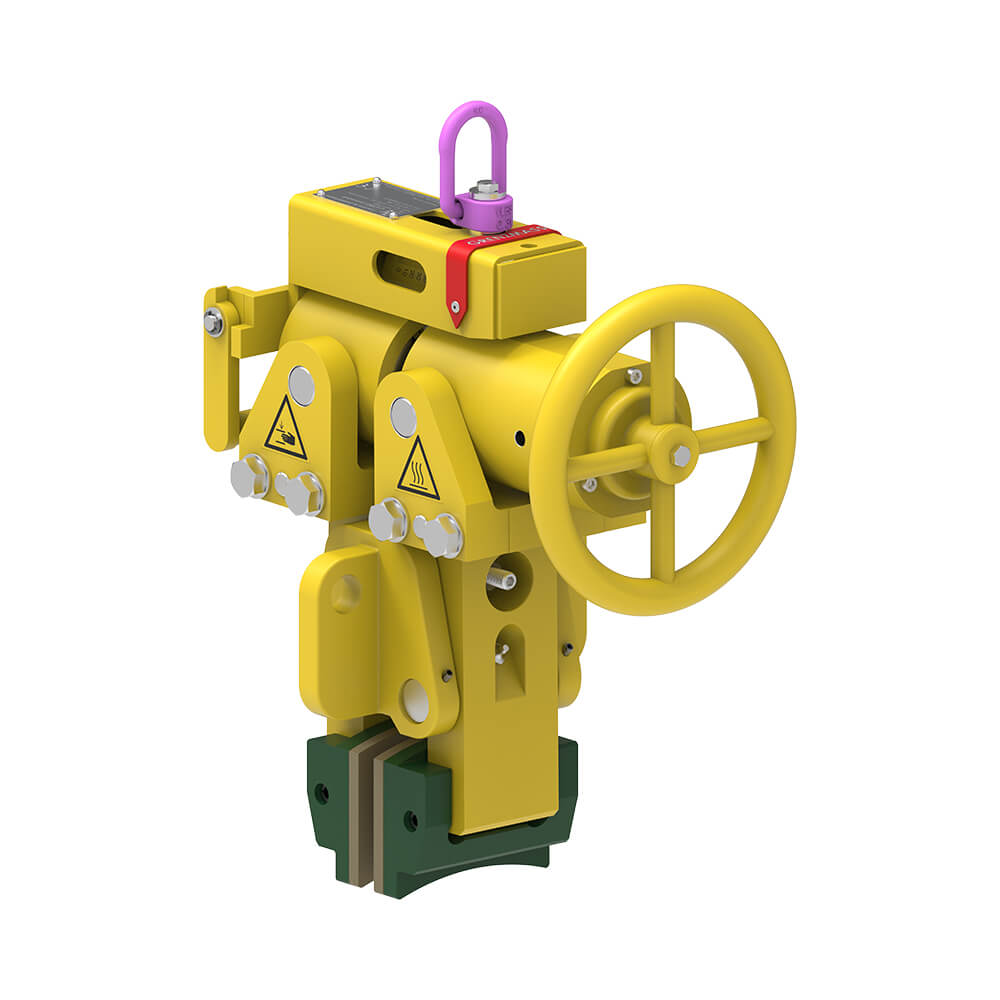

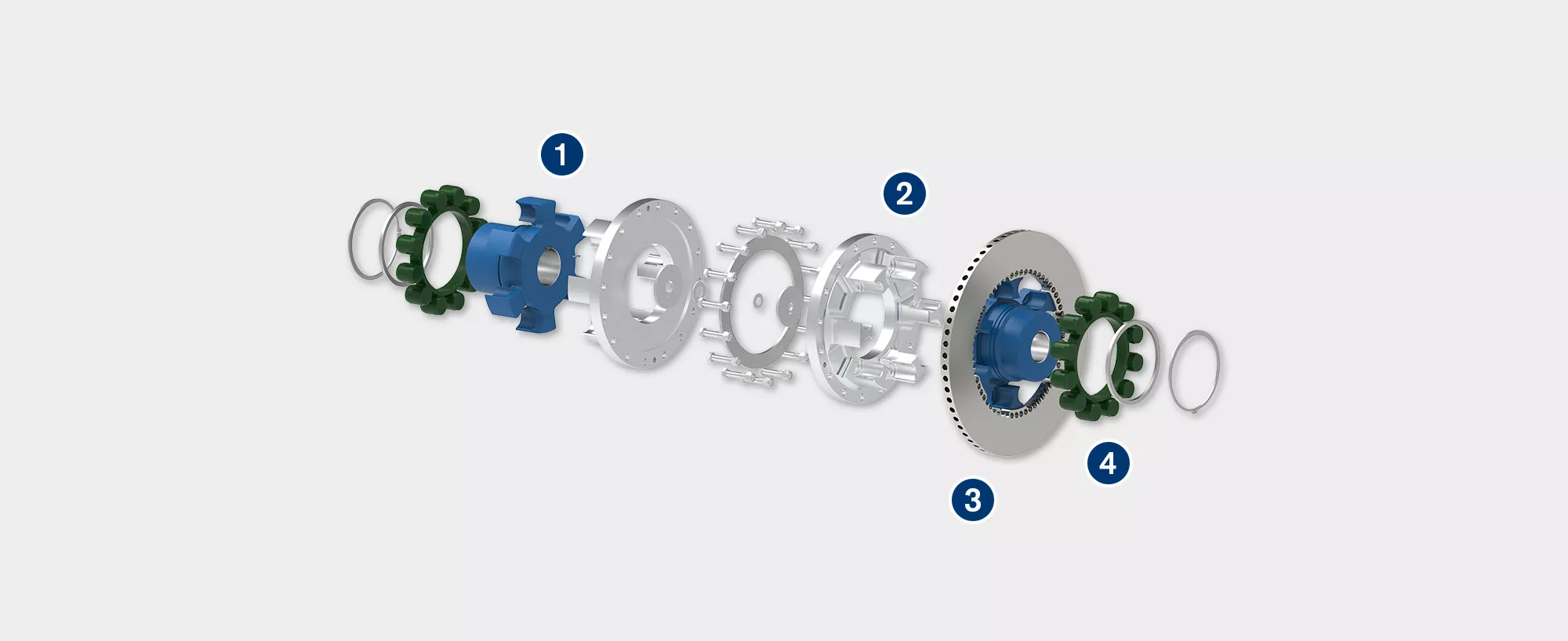

Elastomer Coupling with Brake Disc

The torsionally flexible RINGFEDER® Elastomer Coupling integrated into the Coupling-Brake Systems RINGFEDER® TZS is fail-safe and movable in all directions. It reliably compensates axial, radial, and angular shaft misalignments, which may result from assembly inaccuracies or settling effects – making a significant contribution to the overall system’s service life and operational safety. The elastic intermediate ring of the coupling can be replaced radially without shifting the motor, simplifying maintenance and significantly reducing downtime. Drives operating in the oversynchronous range, such as those used in downward conveying systems, particularly benefit from the use of torsionally flexible couplings. Alternatively, for applications requiring especially smooth acceleration of large masses or shock- and load-free motor start-up and ramp-up, connection via a hydrodynamic coupling is also possible.

1. Claw Hubs

Reliable connection to gearbox and motor

2. Claw Rings

Positive-fit unit for precise and secure power transmission

3. Brake Disc

Internally ventilated and heat-resistant for consistent, reliable braking performance, optionally toothed

4. Elastic Intermediate Rings

Damping of shocks and vibrations as well as compensation of misalignments in all directions, mountable and replaceable radially without shifting the drive unit

Modular System Design

Thanks to the modular design of the Coupling-Brake Systems RINGFEDER® TZS and the associated highly flexible component kit, users benefit from maximum adaptability and application-specific solutions tailored to the exact requirements of their individual use case. All components can be freely combined. The basis is either an elastomer or hydrodynamic coupling including the required brake disc. The selected brake system – either the electromechanical functional brake TZF EL-SA as a spring-applied brake or the manual clamping device TZC – is supplemented according to customer requirements with additional elements such as cover, flanges, torque support units, and sensors. This results in individually configured coupling-brake systems optimally adapted to the specific conditions and demands of the application.

Downloads

Instruction Manual RINGFEDER® Coupling-Brake Systems TZS Functional Brake TCF EL-SA with Position Switch

Instruction Manual RINGFEDER® Coupling-Brake Systems TZS Manual Clamping Device TZC P315

Instruction Manual RINGFEDER® Coupling-Brake Systems TZS Manual Clamping Device TZC P315 with Position Switch

Instruction Manual RINGFEDER® Coupling-Brake Systems TZS Manual Clamping Device TZC P1000

Instruction Manual RINGFEDER® Coupling-Brake Systems TZS Hand Tensioning Device TZC P1000 with Position Switch

RINGFEDER® Product Guide

Further downloads including certificates, instruction manuals and product images are available to you in our Download Center:

DownloadsSuitable Industry Solutions

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.