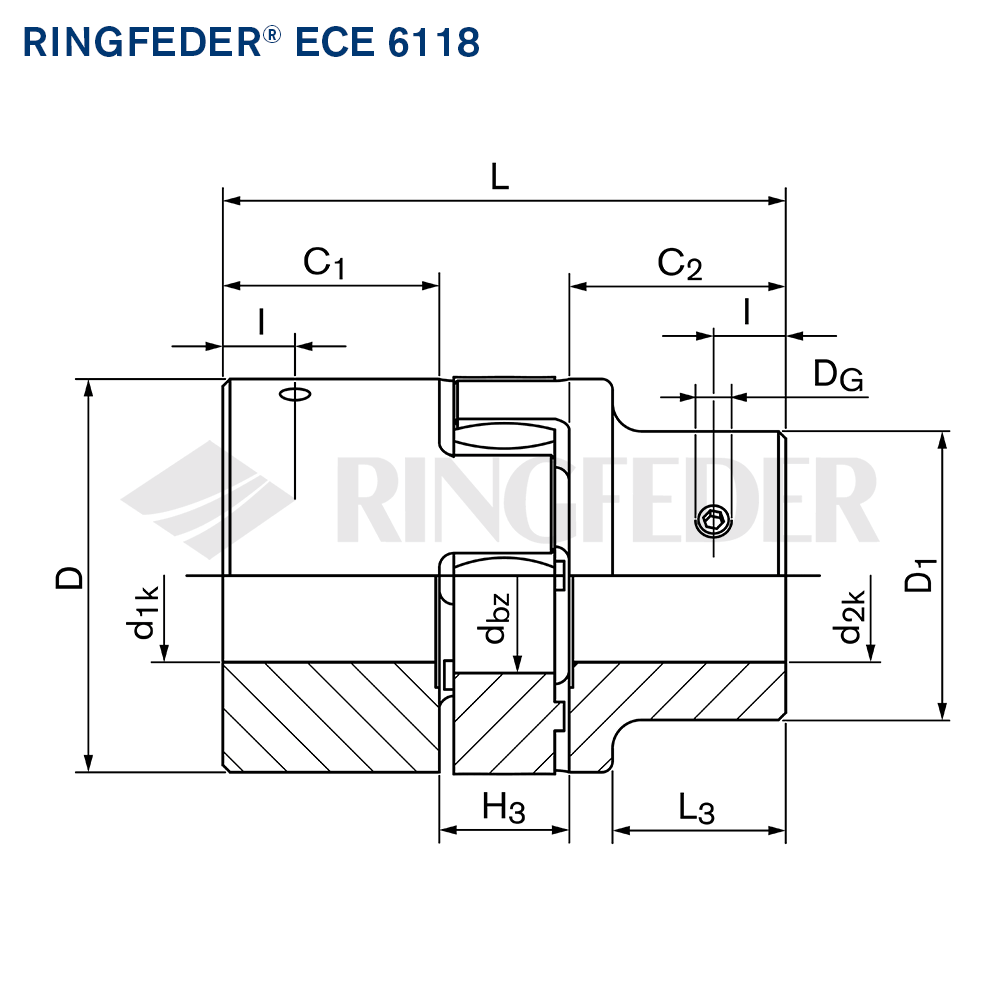

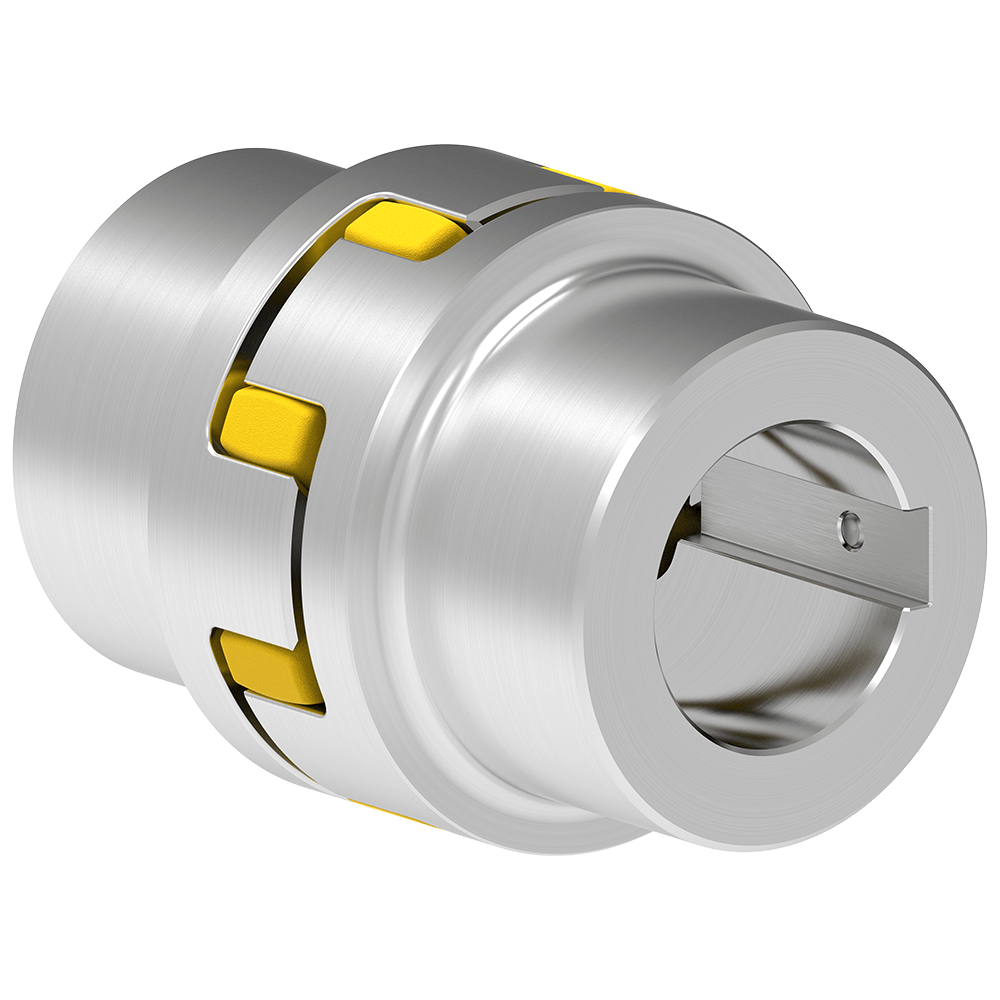

Elastomer Jaw Couplings ECE 6118

Type with Freely Combinable Aluminum Hubs and Elastomer Spiders of Various Hardnesses

- 3 Sizes

- As standard with yellow elastomer spider (92 SH A)

- Bore Diameter d: 6-40 mm (0.236-1.575 inch)

- Outer Diameter D: 40-65 mm (1.575-2.559 inch)

- Overall Length L: 66-140 mm (2.598-5.512 inch)

- Rot. Speed nmax: 11,800-19,000 1/min

- Torque TKN: 10-200 Nm (7.38-147.51 ft·lb)

Technical Data & CAD Models

You require CAD data for this ECE type? Of course, we are more than happy to provide you with these. Contact us quickly and easily via our request form, by e-mail or using the "Need Help?" feature at the bottom right of this site.

| CAD |

Größe/Size

|

NA

|

d1kmin

mm |

d1kmax

mm |

d2kmin

mm |

d2kmax

mm |

D

mm |

D1

mm |

I

mm |

L

mm |

L3

mm |

TKN

Nm |

TA

Nm |

Gw

kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 1 | 6 | 19 | 6 | 19 | 40 | 32 | 10 | 66 | 20 | 10 | 2 | 0,153 | |

| 19 | 1a | 6 | 25 | 6 | 25 | 40 | 40 | 10 | 66 | - | 10 | 2 | 0,201 | |

| 19 | 1b | 6 | 25 | 6 | 25 | 40 | 40 | 10 | 90 | - | 10 | 2 | 0,287 | |

| 24 | 1 | 6 | 24 | 6 | 24 | 55 | 40 | 10 | 78 | 24 | 35 | 2 | 0,299 | |

| 24 | 1a | 6 | 35 | 6 | 35 | 55 | 55 | 10 | 78 | - | 35 | 2 | 0,451 | |

| 24 | 1b | 6 | 35 | 6 | 35 | 55 | 55 | 10 | 118 | - | 35 | 2 | 0,717 | |

| 28 | 1 | 6 | 28 | 6 | 28 | 65 | 48 | 15 | 90 | 28 | 95 | 10 | 0,498 | |

| 28 | 1a | 6 | 40 | 6 | 40 | 65 | 66 | 15 | 90 | - | 95 | 10 | 0,73 | |

| 28 | 1b | 6 | 40 | 6 | 40 | 65 | 65 | 15 | 140 | - | 95 | 10 | 1,192 |

| CAD |

Größe/Size |

NA |

d1kmin inch |

d1kmax inch |

d2kmin inch |

d2kmax inch |

D inch |

D1 inch |

I inch |

L inch |

L3 inch |

TKN ft-lbs |

TA ft-lbs |

Gw lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 1 | 0.236 | 0.748 | 0.236 | 0.748 | 1.5748 | 1.260 | 0.394 | 2.598 | 0.787 | 7.3757 | 1.5 | 0.337 | |

| 19 | 1a | 0.236 | 0.984 | 0.236 | 0.984 | 1.5748 | 1.575 | 0.394 | 2.598 | - | 7.3757 | 1.5 | 0.443 | |

| 19 | 1b | 0.236 | 0.984 | 0.236 | 0.984 | 1.5748 | 1.575 | 0.394 | 3.543 | - | 7.3757 | 1.5 | 0.633 | |

| 24 | 1 | 0.236 | 0.945 | 0.236 | 0.945 | 2.16535 | 1.575 | 0.394 | 3.071 | 0.945 | 25.81495 | 1.5 | 0.659 | |

| 24 | 1a | 0.236 | 1.378 | 0.236 | 1.378 | 2.16535 | 2.165 | 0.394 | 3.071 | - | 25.81495 | 1.5 | 0.994 | |

| 24 | 1b | 0.236 | 1.378 | 0.236 | 1.378 | 2.16535 | 2.165 | 0.394 | 4.646 | - | 25.81495 | 1.5 | 1.581 | |

| 28 | 1 | 0.236 | 1.102 | 0.236 | 1.102 | 2.55905 | 1.890 | 0.591 | 3.543 | 1.102 | 70.06915 | 7.4 | 1.098 | |

| 28 | 1a | 0.236 | 1.575 | 0.236 | 1.575 | 2.55905 | 2.598 | 0.591 | 3.543 | - | 70.06915 | 7.4 | 1.609 | |

| 28 | 1b | 0.236 | 1.575 | 0.236 | 1.575 | 2.55905 | 2.559 | 0.591 | 5.512 | - | 70.06915 | 7.4 | 2.628 |

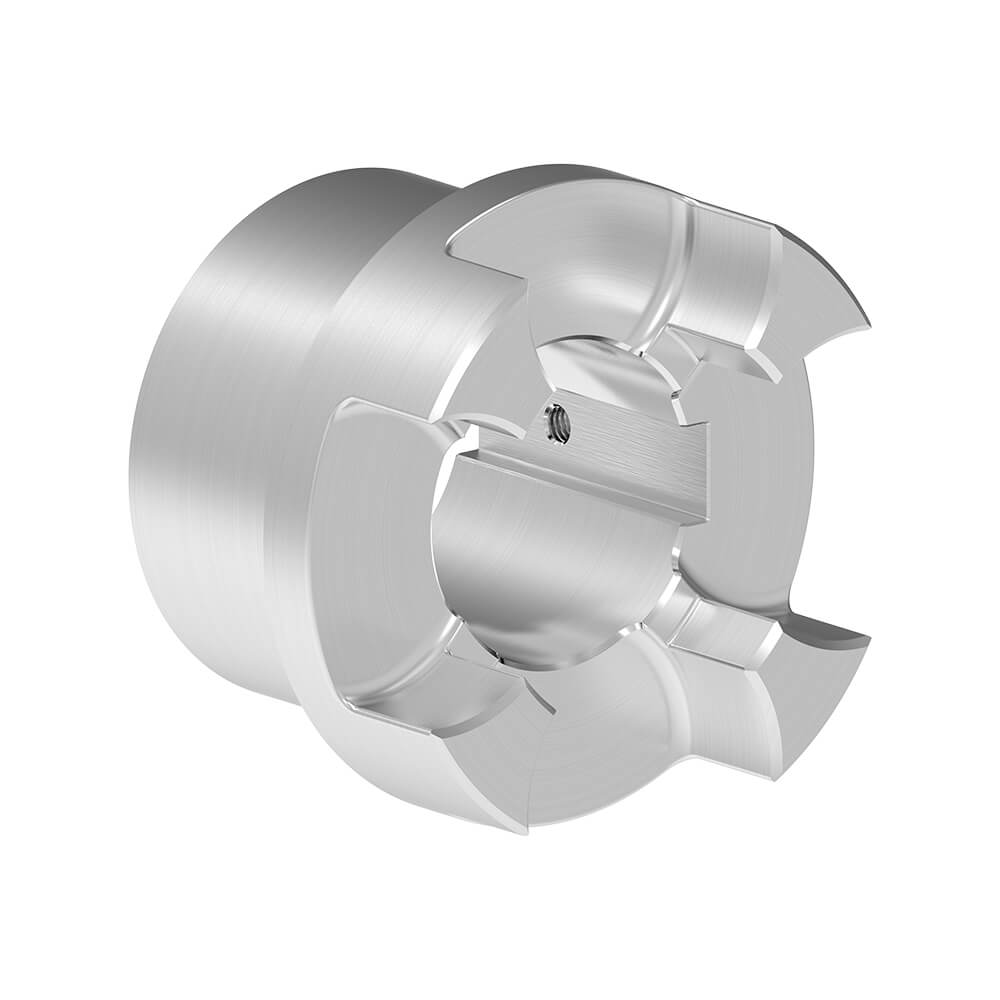

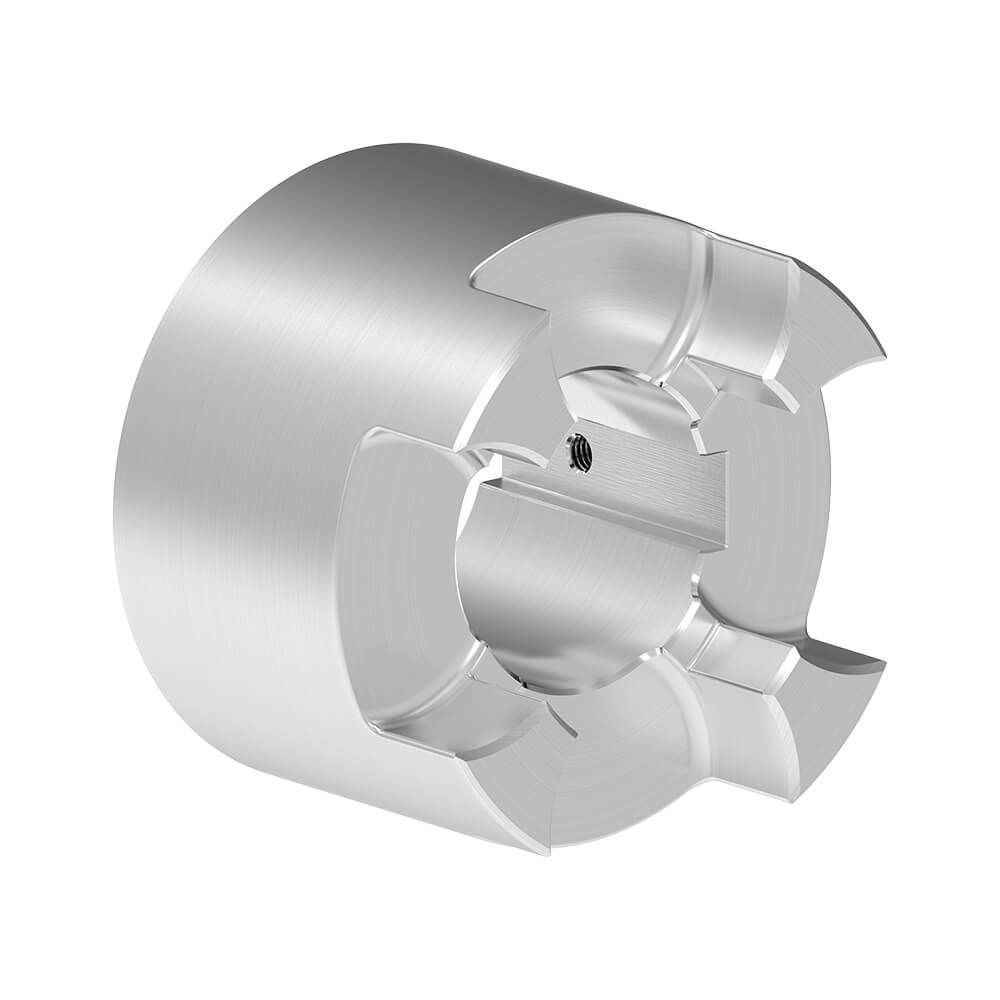

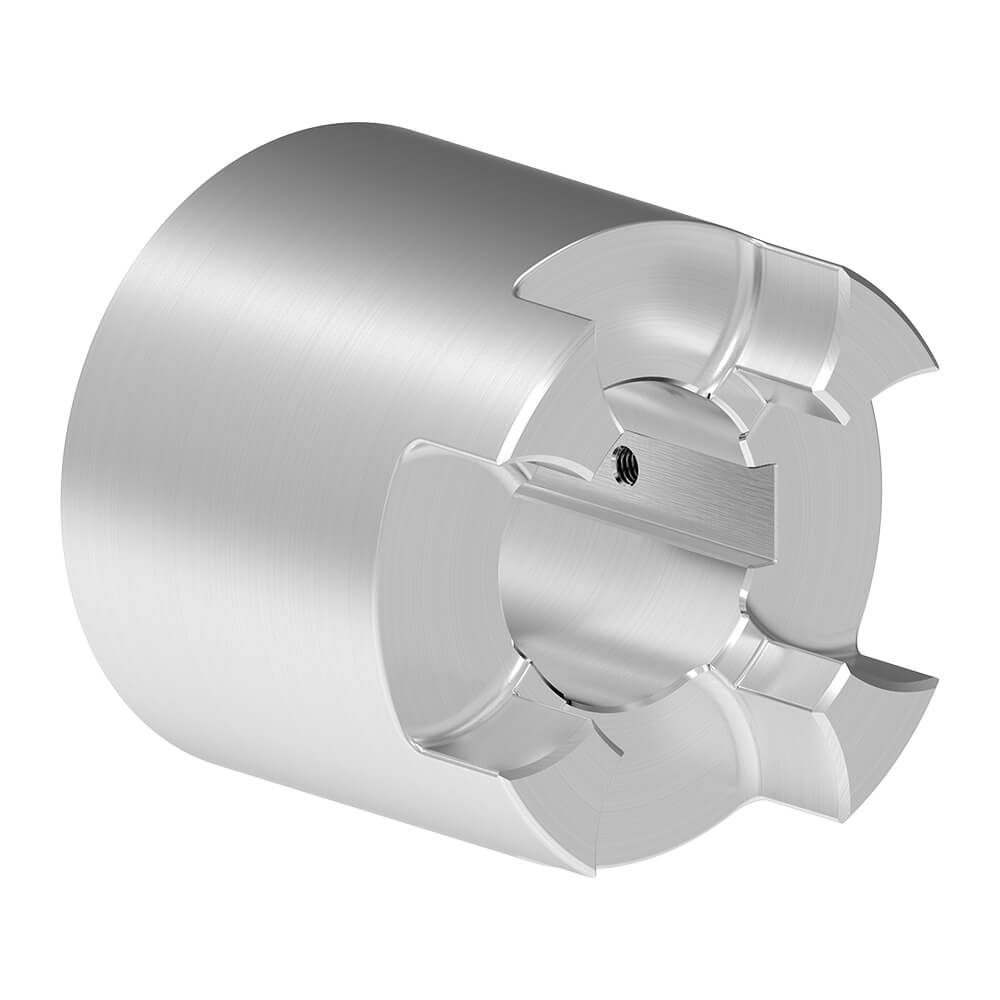

Images & Drawings

Technical Data of Elastomer Spiders

| CAD |

Größe/Size

|

SH

|

nmax

1/min |

nmax

1/min |

TKN

Nm |

TKW

Nm |

TKmax

Nm |

ψ

|

CTdyn (1 TKN)

103 Nm/rad |

CTdyn (0,5 TKN)

103 Nm/rad |

CTdyn (0,25 TKN)

103 Nm/rad |

dbZ

mm |

ΔKa (1500)

mm |

ΔKr (1500)

mm |

ΔKw (1500)

Degrees |

φ TKmax

Degrees |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 64 SH D | 19000 | 16700 | 21 | 5,5 | 42 | 0,75 | 1,99 | 1,37 | 0,98 | 18 | -0,5 +1,2 | 0,13 | 1,1 | 3,6 | |

| 19 | 92 SH A | 19000 | 16700 | 10 | 2,6 | 20 | 0,8 | 0,52 | 0,34 | 0,24 | 18 | -0,5 +1,2 | 0,2 | 1,2 | 5 | |

| 19 | 98 SH A | 19000 | 16700 | 17 | 4,4 | 34 | 0,8 | 1,59 | 1,16 | 0,80 | 18 | -0,5 +1,2 | 0,2 | 1,2 | 5 | |

| 24 | 64 SH D | 14000 | 12100 | 75 | 19,5 | 150 | 0,75 | 7,92 | 5,45 | 3,91 | 27 | -0.5 +1.4 | 0,15 | 0,8 | 3,6 | |

| 24 | 92 SH A | 14000 | 12100 | 35 | 9,1 | 70 | 0,8 | 1,96 | 1,29 | 0,92 | 27 | -0,5 +1,4 | 0,22 | 0,9 | 5 | |

| 24 | 98 SH A | 14000 | 12100 | 60 | 16 | 120 | 0,8 | 6,24 | 4,53 | 3,14 | 27 | -0,5 +1,4 | 0,22 | 0,9 | 5 | |

| 28 | 64 SH D | 11800 | 10100 | 200 | 52 | 400 | 0,75 | 18,88 | 12,98 | 9,31 | 30 | -0,7 +1,5 | 0,18 | 0,8 | 3,6 | |

| 28 | 92 SH A | 11800 | 10100 | 95 | 25 | 190 | 0,8 | 4,95 | 3,24 | 2,32 | 30 | -0,7 +1,5 | 0,25 | 0,9 | 5 | |

| 28 | 98 SH A | 11800 | 10100 | 160 | 42 | 320 | 0,8 | 15,32 | 11,12 | 7,71 | 30 | -0,7 +1,5 | 0,25 | 0,9 | 5 | |

| 38 | 64 SH D | 9500 | 8300 | 405 | 105 | 810 | 0,75 | 38,14 | 22,41 | 15,54 | 38 | -0,7 +1,8 | 0,21 | 0,9 | 3,6 | |

| 38 | 92 SH A | 9500 | 8300 | 190 | 49 | 380 | 0,8 | 9,80 | 6,42 | 4,59 | 38 | -0,7 +1,8 | 0,28 | 1 | 5 | |

| 38 | 98 SH A | 9500 | 8300 | 325 | 85 | 650 | 0,8 | 30,89 | 22,41 | 15,54 | 38 | -0,7 +1,8 | 0,28 | 1 | 5 | |

| 42 | 64 SH D | 8000 | 7000 | 560 | 146 | 1120 | 0,75 | 60,40 | 45,50 | 29,80 | 46 | -1 +2 | 0,23 | 0,9 | 3,6 | |

| 42 | 92 SH A | 8000 | 7000 | 265 | 69 | 530 | 0,8 | 15,40 | 10,40 | 7,40 | 46 | -1 +2 | 0,32 | 1 | 5 | |

| 42 | 98 SH A | 8000 | 7000 | 450 | 117 | 900 | 0,8 | 45,50 | 33,20 | 23,00 | 46 | -1 +2 | 0,32 | 1 | 5 | |

| 48 | 64 SH D | 7100 | 6350 | 655 | 170 | 1310 | 0,75 | 71,00 | 53,50 | 35,00 | 51 | -1 +2,1 | 0,25 | 1 | 3,6 | |

| 48 | 92 SH A | 7100 | 6350 | 310 | 81 | 620 | 0,8 | 17,80 | 12,00 | 8,60 | 51 | -1 +2,1 | 0,36 | 1,1 | 5 | |

| 48 | 98 SH A | 7100 | 6350 | 525 | 137 | 1050 | 0,8 | 52,30 | 38,10 | 26,40 | 51 | -1 +2,1 | 0,36 | 1,1 | 5 | |

| 55 | 64 SH D | 6300 | 5550 | 825 | 215 | 1650 | 0,75 | 92,30 | 69,50 | 45,50 | 60 | -1 +2,2 | 0,27 | 1 | 3,6 | |

| 55 | 92 SH A | 6300 | 5550 | 410 | 107 | 820 | 0,8 | 24,50 | 16,50 | 11,80 | 60 | -1 +2,2 | 0,38 | 1,1 | 5 | |

| 55 | 98 SH A | 6300 | 5550 | 685 | 178 | 1370 | 0,8 | 70,60 | 51,40 | 35,60 | 60 | -1 +2,2 | 0,38 | 1,1 | 5 | |

| 65 | 64 SH D | 5600 | 4950 | 1175 | 306 | 2350 | 0,75 | 141,10 | 102,50 | 59,80 | 68 | -1 +2,6 | 0,3 | 1,1 | 3,6 | |

| 65 | 92 SH A | 5600 | 4950 | 590 | 160 | 1220 | 0,8 | 40,40 | 27,80 | 19,80 | 68 | -1 +2,6 | 0,42 | 1,2 | 5 | |

| 65 | 98 SH A | 5600 | 4950 | 940 | 244 | 1880 | 0,8 | 100,70 | 73,70 | 51,00 | 68 | -1 +2,6 | 0,42 | 1,2 | 5 | |

| 75 | 64 SH D | 4750 | 4150 | 2400 | 624 | 4800 | 0,75 | 294,40 | 213,80 | 124,80 | 80 | -1,5 +3 | 0,34 | 1,1 | 3,6 | |

| 75 | 92 SH A | 4750 | 4150 | 1220 | 326 | 2500 | 0,8 | 84,60 | 58,10 | 41,40 | 80 | -1,5 +3 | 0,48 | 1,2 | 5 | |

| 75 | 98 SH A | 4750 | 4150 | 1920 | 499 | 3840 | 0,8 | 209,60 | 153,50 | 106,30 | 80 | -1,5 +3 | 0,48 | 1,2 | 5 | |

| 90 | 64 SH D | 3800 | 3300 | 4500 | 1128 | 9000 | 0,75 | 550,50 | 338,40 | 183,30 | 100 | -1,5 +3,4 | 0,36 | 1,1 | 3,6 | |

| 90 | 92 SH A | 3800 | 3300 | 2350 | 610 | 4700 | 0,8 | 158,70 | 109,10 | 77,70 | 100 | -1,5 +3,4 | 0,5 | 1,2 | 5 | |

| 90 | 98 SH A | 3800 | 3300 | 3550 | 880 | 7100 | 0,8 | 413,40 | 273,00 | 134,20 | 100 | -1,5 +3,4 | 0,5 | 1,2 | 5 |

Suitable Industry Solutions

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.