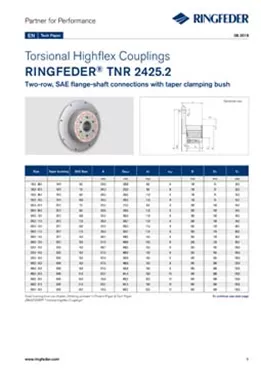

Torsional Highflex Couplings TNR 2425.2

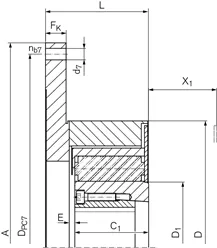

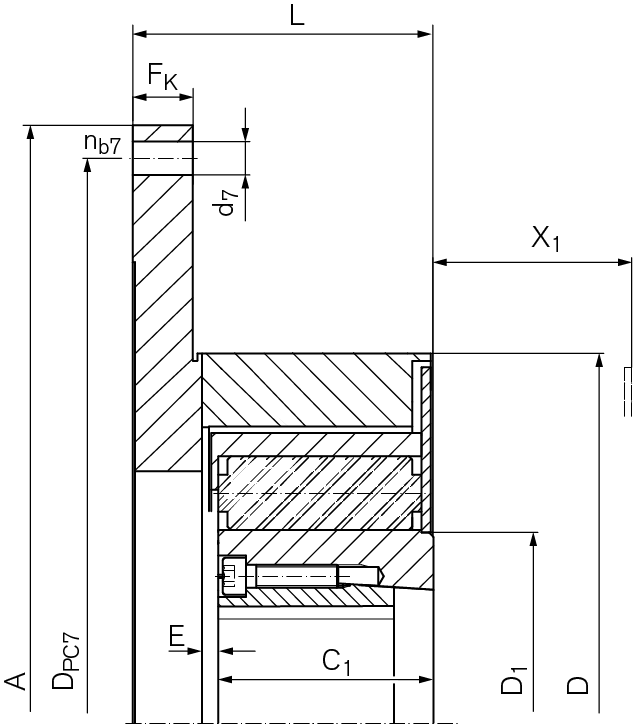

Double-row torsional highflex RINGFEDER® TNR 2425.2 for flange-shaft connection and taper lock bushing systems, flange dimensions acc. to SAE J 620 d. In mind of X1 easy replacement of the elastic elements without axial movement of the coupled machines.

Technical Data & CAD Models

| CAD |

Size

|

Taper bushing

|

SAE Size

|

A

mm |

DPC7

mm |

d7

mm |

D

mm |

C1

mm |

L

mm |

FK

mm |

X1

mm |

Gwub

kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 160.2 - 06.5 | 1615 | 6,5 | 215,9 | 200,0 | 9,5 | 160 | 52,0 | 71 | 15 | 41 | 3,7 | |

| 160.2 - 07.5 | 1615 | 7,5 | 241,3 | 222,3 | 9,5 | 160 | 52,0 | 71 | 15 | 41 | 4,0 | |

| 160.2 - 08.0 | 1615 | 8,0 | 263,5 | 244,5 | 11,0 | 160 | 52,0 | 71 | 15 | 41 | 4,3 | |

| 160.2 - 10.0 | 1615 | 10,0 | 314,3 | 295,3 | 11,0 | 160 | 52,0 | 71 | 15 | 41 | 5,2 | |

| 200.2 - 07.5 | 2012 | 7,5 | 222,3 | 213,3 | 9,5 | 200 | 64,0 | 84 | 18 | 50 | 6,8 | |

| 200.2 - 08.0 | 2012 | 8,0 | 263,5 | 244,5 | 11,0 | 200 | 64,0 | 84 | 18 | 50 | 7,2 | |

| 200.2 - 10.0 | 2012 | 10,0 | 314,3 | 295,3 | 11,0 | 200 | 64,0 | 84 | 18 | 50 | 8,3 | |

| 200.2 - 11.5 | 2012 | 11,5 | 352,4 | 333,7 | 11,0 | 200 | 64,0 | 84 | 18 | 50 | 9,2 | |

| 260.2 - 10.0 | 2517 | 10,0 | 314,3 | 295,3 | 11,0 | 260 | 80,0 | 104 | 24 | 64 | 15,2 | |

| 260.2 - 11.5 | 2517 | 11,5 | 352,4 | 333,7 | 11,0 | 260 | 80,0 | 104 | 24 | 64 | 16,4 | |

| 260.2 - 14.0 | 2517 | 14,0 | 466,7 | 438,2 | 14,5 | 260 | 80,0 | 104 | 24 | 64 | 20,5 | |

| 260.2 - 16.0 | 2517 | 16,0 | 517,5 | 489,0 | 14,5 | 260 | 80,0 | 104 | 24 | 64 | 22,9 | |

| 320.2 - 14.0 | 3535 | 14,0 | 466,7 | 438,2 | 14,5 | 320 | 100,0 | 132 | 26 | 80 | 30,1 | |

| 320.2 - 16.0 | 3535 | 16,0 | 517,5 | 489,0 | 14,5 | 320 | 100,0 | 132 | 26 | 80 | 32,7 | |

| 320.2 - 18.0 | 3535 | 18,0 | 571,5 | 542,9 | 18,0 | 320 | 100,0 | 132 | 26 | 80 | 35,7 | |

| 400.2 - 16.0 | 4040 | 16,0 | 517,5 | 489,0 | 14,5 | 400 | 125,0 | 162 | 31 | 100 | 57,1 | |

| 400.2 - 18.0 | 4040 | 18,0 | 571,5 | 542,9 | 18,0 | 400 | 125,0 | 162 | 31 | 31 | 60,7 | |

| 400.2 - 21.0 | 4040 | 21,0 | 673,1 | 641,4 | 18,0 | 400 | 125,0 | 162 | 31 | 100 | 68,4 | |

| 400.2 - 24.0 | 4040 | 24,0 | 733,4 | 692,2 | 22,0 | 400 | 125,0 | 162 | 31 | 100 | 72,8 | |

| 500.2 - 21.0 | 5050 | 21,0 | 673,1 | 641,4 | 18,0 | 500 | 156,0 | 197 | 34 | 126 | 114,0 | |

| 500.2 - 24.0 | 5050 | 24,0 | 733,4 | 692,2 | 22,0 | 500 | 156,0 | 197 | 34 | 126 | 118,0 |

| CAD |

Size |

Taper bushing |

SAE Size |

A inch |

DPC7 inch |

d7 inch |

D inch |

C1 inch |

L inch |

FK inch |

X1 inch |

Gwub lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 160.2 - 06.5 | 1615 | 6.5 | 8.500 | 7.875 | 0.374 | 6.299 | 2.047 | 2.795 | 0.591 | 1.614 | 8.2 | |

| 160.2 - 07.5 | 1615 | 7.5 | 9.500 | 8.752 | 0.374 | 6.299 | 2.047 | 2.795 | 0.591 | 1.614 | 8.8 | |

| 160.2 - 08.0 | 1615 | 8.0 | 10.374 | 9.625 | 0.433 | 6.299 | 2.047 | 2.795 | 0.591 | 1.614 | 9.6 | |

| 160.2 - 10.0 | 1615 | 10.0 | 12.375 | 11.625 | 0.433 | 6.299 | 2.047 | 2.795 | 0.591 | 1.614 | 11.5 | |

| 200.2 - 07.5 | 2012 | 7.5 | 8.750 | 8.398 | 0.374 | 7.874 | 2.520 | 3.307 | 0.709 | 1.969 | 15.0 | |

| 200.2 - 08.0 | 2012 | 8.0 | 10.374 | 9.625 | 0.433 | 7.874 | 2.520 | 3.307 | 0.709 | 1.969 | 15.9 | |

| 200.2 - 10.0 | 2012 | 10.0 | 12.375 | 11.625 | 0.433 | 7.874 | 2.520 | 3.307 | 0.709 | 1.969 | 18.2 | |

| 200.2 - 11.5 | 2012 | 11.5 | 13.875 | 13.139 | 0.433 | 7.874 | 2.520 | 3.307 | 0.709 | 1.969 | 20.2 | |

| 260.2 - 10.0 | 2517 | 10.0 | 12.375 | 11.625 | 0.433 | 10.236 | 3.150 | 4.094 | 0.945 | 2.520 | 33.5 | |

| 260.2 - 11.5 | 2517 | 11.5 | 13.875 | 13.139 | 0.433 | 10.236 | 3.150 | 4.094 | 0.945 | 2.520 | 36.2 | |

| 260.2 - 14.0 | 2517 | 14.0 | 18.375 | 17.250 | 0.571 | 10.236 | 3.150 | 4.094 | 0.945 | 2.520 | 45.3 | |

| 260.2 - 16.0 | 2517 | 16.0 | 20.375 | 19.252 | 0.571 | 10.236 | 3.150 | 4.094 | 0.945 | 2.520 | 50.6 | |

| 320.2 - 14.0 | 3535 | 14.0 | 18.375 | 17.250 | 0.571 | 12.598 | 3.937 | 5.197 | 1.024 | 3.150 | 66.3 | |

| 320.2 - 16.0 | 3535 | 16.0 | 20.375 | 19.252 | 0.571 | 12.598 | 3.937 | 5.197 | 1.024 | 3.150 | 72.0 | |

| 320.2 - 18.0 | 3535 | 18.0 | 22.501 | 21.374 | 0.709 | 12.598 | 3.937 | 5.197 | 1.024 | 3.150 | 78.8 | |

| 400.2 - 16.0 | 4040 | 16.0 | 20.375 | 19.252 | 0.571 | 15.748 | 4.921 | 6.378 | 1.220 | 3.937 | 125.8 | |

| 400.2 - 18.0 | 4040 | 18.0 | 22.501 | 21.374 | 0.709 | 15.748 | 4.921 | 6.378 | 1.220 | 1.220 | 133.9 | |

| 400.2 - 21.0 | 4040 | 21.0 | 26.500 | 25.252 | 0.709 | 15.748 | 4.921 | 6.378 | 1.220 | 3.937 | 150.8 | |

| 400.2 - 24.0 | 4040 | 24.0 | 28.875 | 27.252 | 0.866 | 15.748 | 4.921 | 6.378 | 1.220 | 3.937 | 160.6 | |

| 500.2 - 21.0 | 5050 | 21.0 | 26.500 | 25.252 | 0.709 | 19.685 | 6.142 | 7.756 | 1.339 | 4.961 | 251.3 | |

| 500.2 - 24.0 | 5050 | 24.0 | 28.875 | 27.252 | 0.866 | 19.685 | 6.142 | 7.756 | 1.339 | 4.961 | 260.1 |

Images & Drawings

Product Characteristics

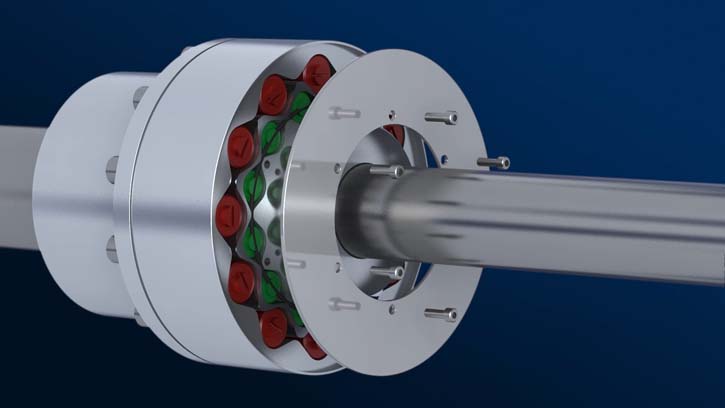

RINGFEDER® TNR

The RINGFEDER® TNR coupling has specifically been designed and optimized for use primarily in internal combustion engines. In such applications, dynamic disturbances are caused by periodic excitation and utilization of a large speed range. It is therefore necessary to shift unavoidable resonances by deliberately adjusting the stiffness.

The new RINGFEDER® TNR – a compact, plug-in configuration, optionally available as puncture-proof or not fail-safe design, and dynamically adjustable over a wide temperature range.

Key data:

- Dynamic stiffness: elastic to highly elastic transmission capability

- Torque [Nm]: 144 to 9600

- Speed [rpm]: 1200 to 4750

- Temperature range: -50°C to +230°C

Every drive line has its characteristic torsional vibration behaviour and the newly developed coupling RINGFEDER® TNR ensures optimum tuning of the dynamic stiffness to suit any application.

Properties/Benefits

- Purposeful adjustment of the dynamic properties by varying the elastomeric bufferst

- Not fail safe, but can be made puncture-proof by simple modification

- Very compact design allows installation in confined spaces

- Easy replacement of wear parts without having to remove the hubs or flanges

- On account of the modular construction system, even custom solutions can be realized at low cost

- Cost-neutral adaptation of the stiffness, also for individual projects.

- Taper bushing bore see catalog page 32

Downloads

Product Paper Torsional Highflex Couplings RINGFEDER® TNR

Tech Paper Torsional Highflex Couplings RINGFEDER® TNR 2425.2

Instruction Manual Torsional Highflex Couplings RINGFEDER® TNR

Further downloads including certificates, instruction manuals and product images are available to you in our Download Center:

Downloads