Shock Absorbing Elements DEFORM plus® R/RMP

Due to the guidance at the fastening screw this version allows additional light lateral forces.

Technical Data & CAD Models

You require CAD data for this product? Of course, we are more than happy to provide you with these. Contact us quickly and easily via our request form, by e-mail or using the "Need Help?" feature at the bottom right of this site.

| CAD |

Typ

|

Wmax(20°C)/6h

Joule |

Wmax(20°C)/1h

Joule |

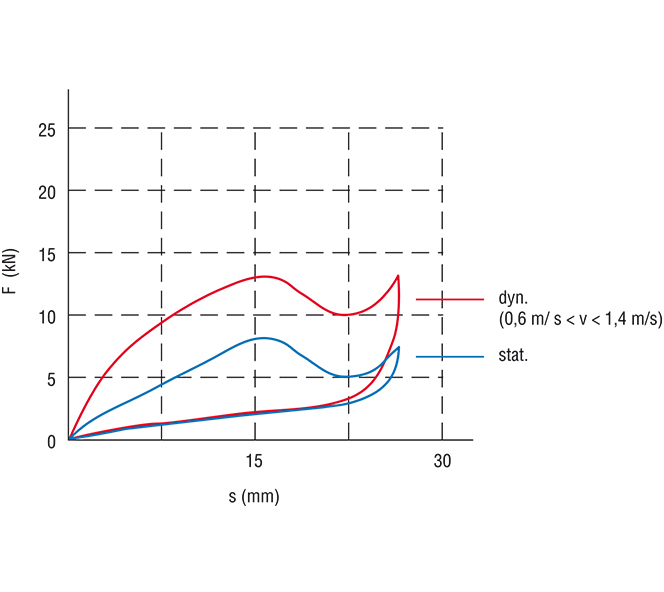

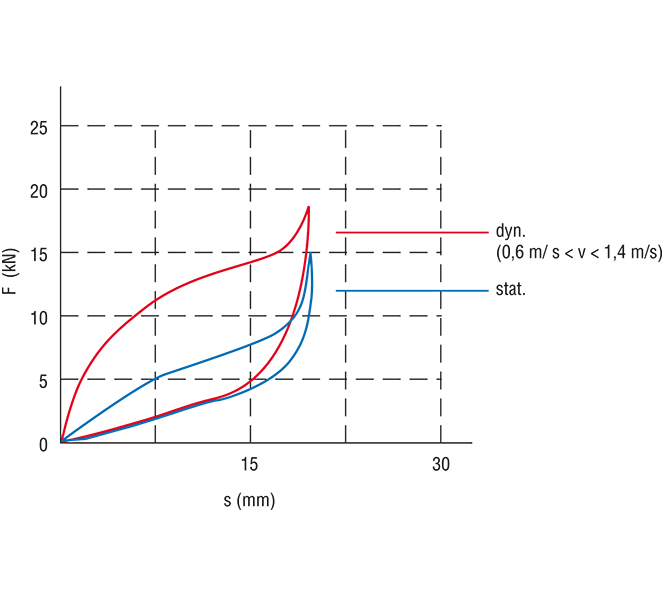

Fdyn(20°C) ~ 2xFstat(20°C)

kN |

smax

mm |

D'

mm |

D1.

mm |

DB

mm |

L

mm |

DG

mm |

tE mm |

Gw

kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R45 | 240 | 15 (bei 1,4 m/s) | 27 | 68 | 45 | 54 | 8 | 17 | 0,085 | |||

| R60 | 560 | 30 (bei 2,0 m/s) | 36 | 91 | 60 | 72 | 12 | 17 | 0,240 | |||

| R45MP | 180 | 20 (bei 1,4 m/s) | 19 | 65 | 45 | 57 | 63 | 12 | 25 | 0,160 | ||

| R60MP | 420 | 40 (bei 2,0 m/s) | 25 | 90 | 60 | 71 | 85 | 16 | 22 | 0,360 |

| CAD |

Typ |

Wmax(20°C)/6h ft-lbs |

Wmax(20°C)/1h ft-lbs |

Fdyn(20°C) ~ 2xFstat(20°C) lbs |

smax inch |

D' inch |

D1. inch |

DB inch |

L inch |

DG mm |

tE inch |

Gw lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R45 | 177 | 3,371 | 1.063 | 2.677 | 1.772 | 2.126 | 8 | 0.669 | 0.187 | |||

| R60 | 413 | 6,742 | 1.417 | 3.583 | 2.362 | 2.835 | 12 | 0.669 | 0.529 | |||

| R45MP | 133 | 4,495 | 0.748 | 2.559 | 1.772 | 2.244 | 2.480 | 12 | 0.984 | 0.353 | ||

| R60MP | 310 | 8,989 | 0.984 | 3.543 | 2.362 | 2.795 | 3.346 | 16 | 0.866 | 0.794 |

Images & Drawings

Product Characteristics

SHOCK ABSORBING Elements DEFORM plus® R/RMP

Reusable buffer for absorption of kinetic energies without additional spring.

The casing combines the function of a spring and a damper. It can be reused after a dynamic load. Dependent on the velocity, the maximum supporting load automatically adapts to the impact energy, which means that i.e. equal masses are retarded more softly at lower velocities.

Working temperature: -10°C up to +50°C.

Ambient conditions:

The material is resistant to

- Bleach liquor 3%

- Sugar solution 30%

- Hydrogen peroxide 10%

- Ammonia 5%

- Acetic acid 2%

- Formic acid 2%

- Linseed fatty acid

- Tannic acid solution 20%

- Lubrication grease and oil

A continuous contact with water should be avoided. In accordance with DIN 4012, building material class 2, the material is classified as non-combustible, dripping (off).

Suitable Industry Solutions

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.